Mini-Facade

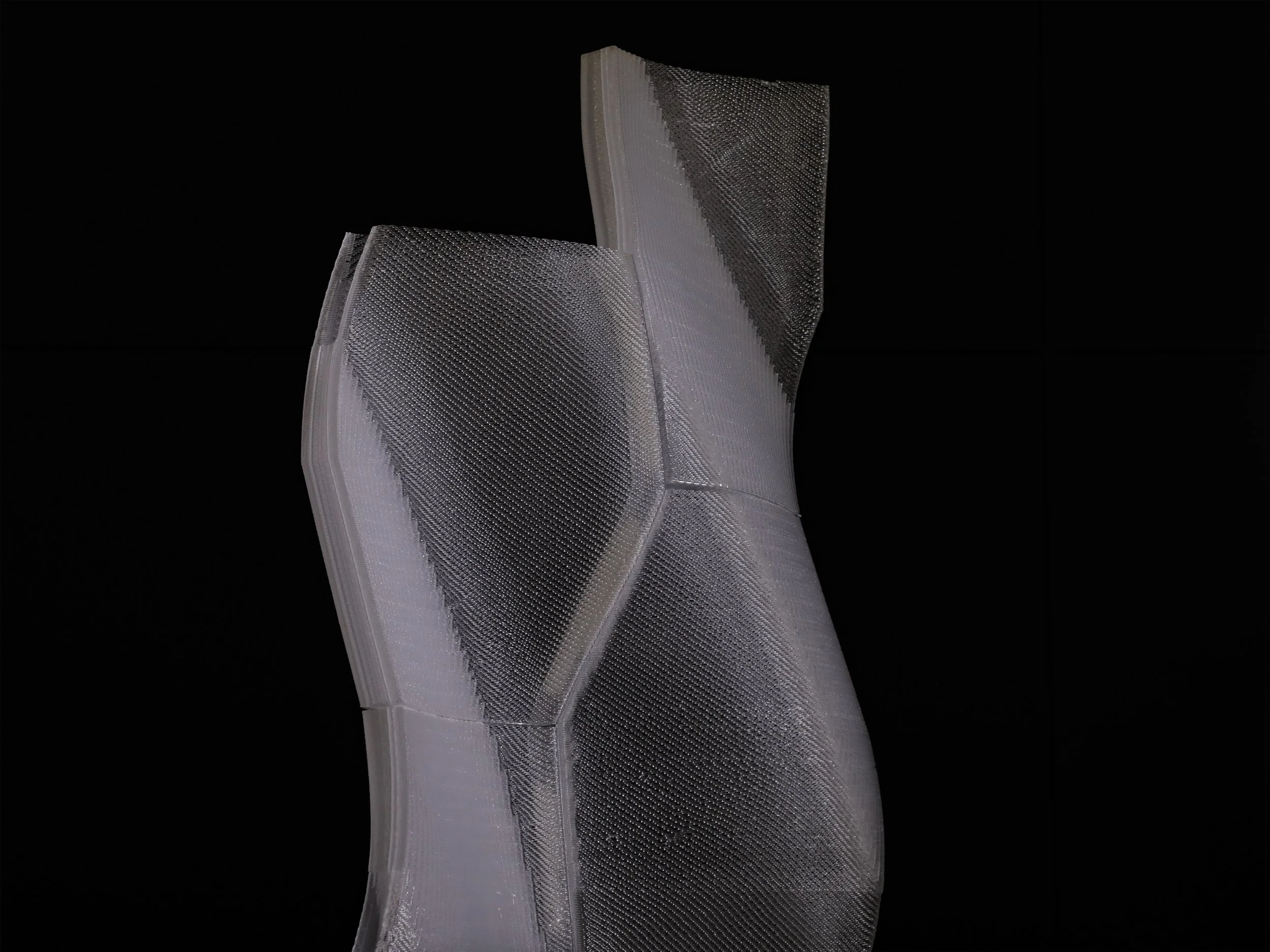

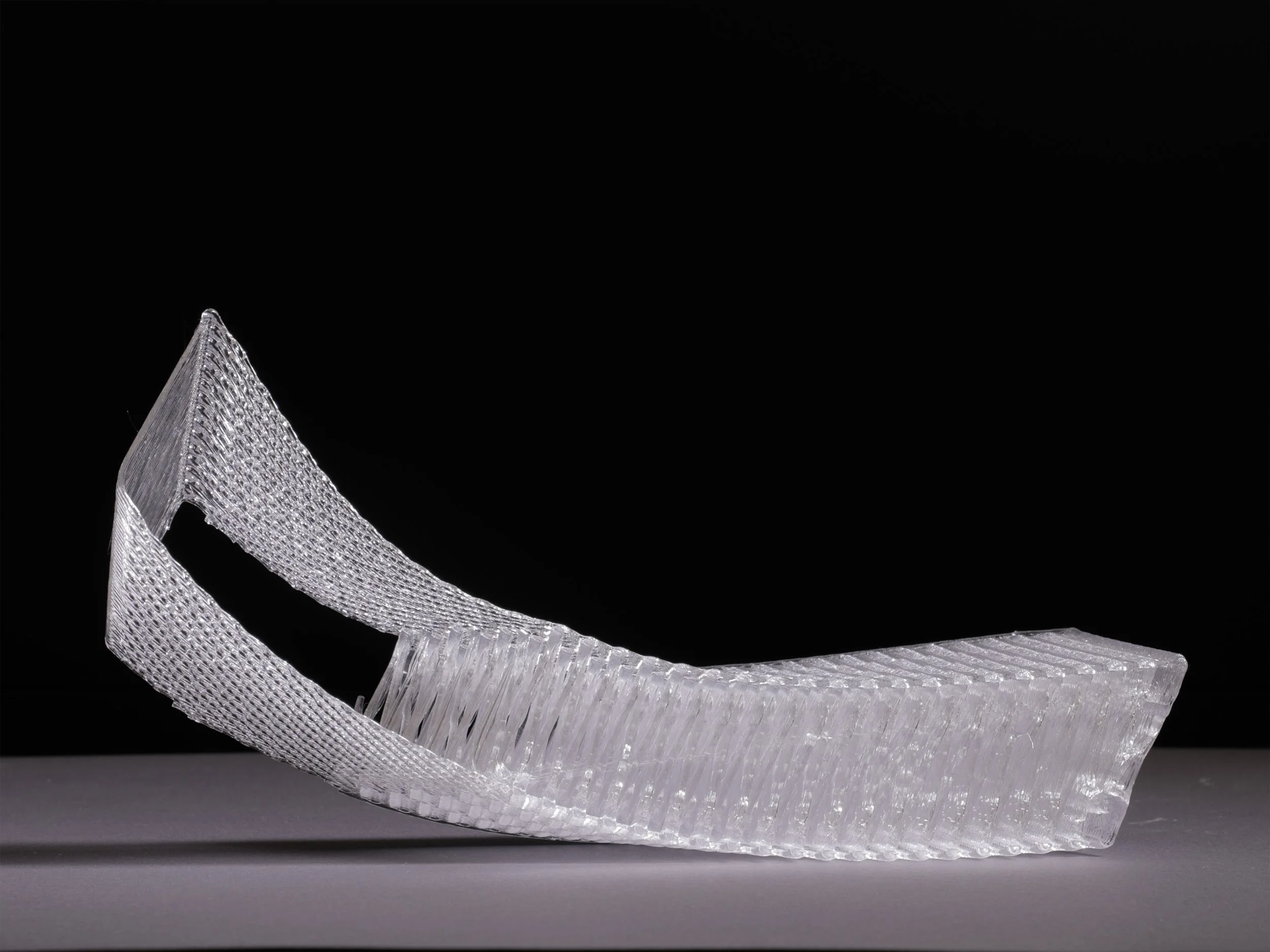

Mini Facade is an intensive teaching module within the MAS DFAB program that introduces students to the design and fabrication of 3D-printed facade systems using collaborative robotic setups. The course focuses on recycled PETG as a primary material and frames the building envelope as a performative system, linking geometry, material behavior, and fabrication logic.

Students work in small groups, each operating an individual robotic 3D printing setup. Through parallel experimentation, the module explores multiple architectural aspects of additively manufactured facades, allowing students to compare design strategies across teams while working within shared material and machine constraints.

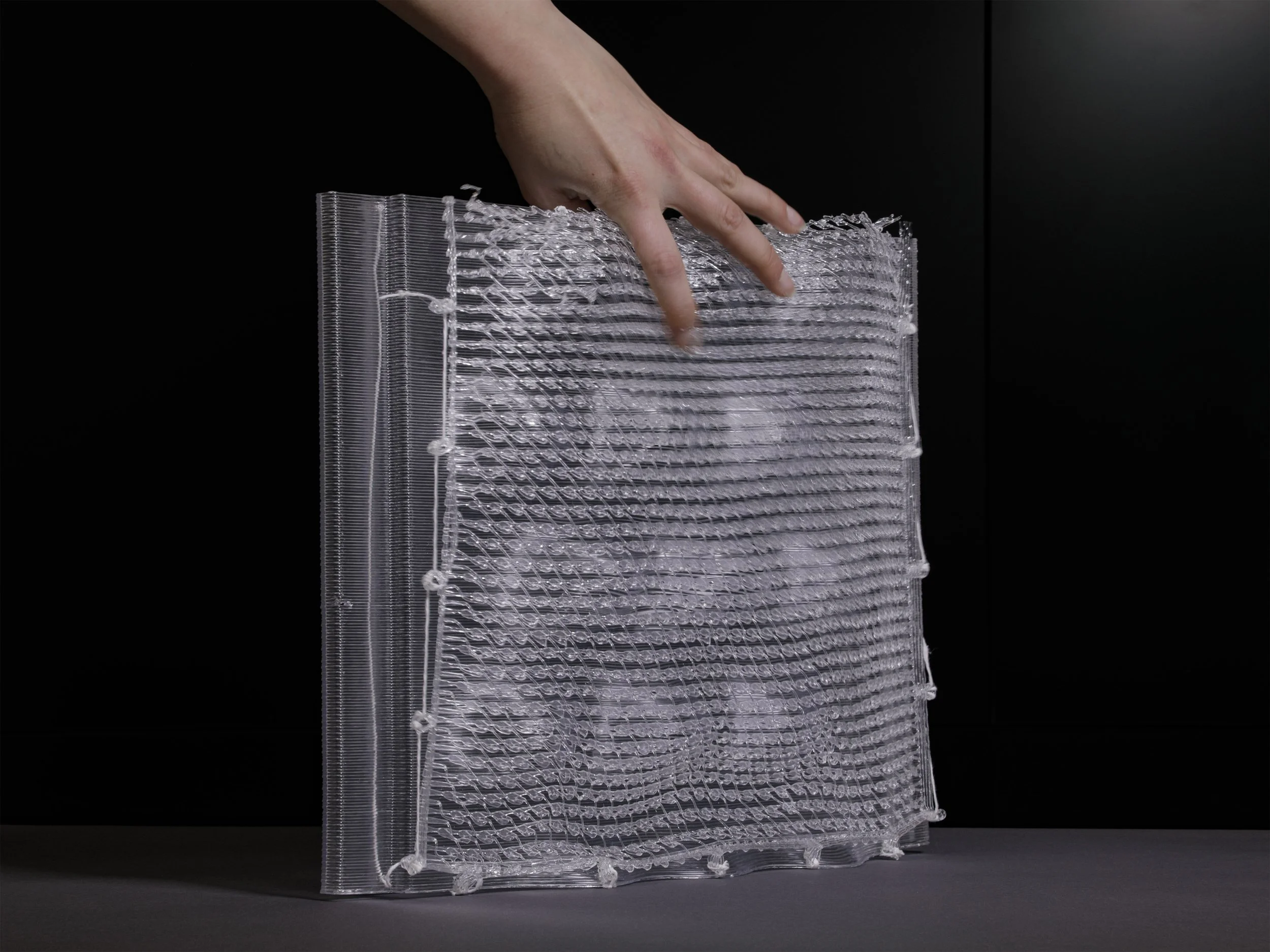

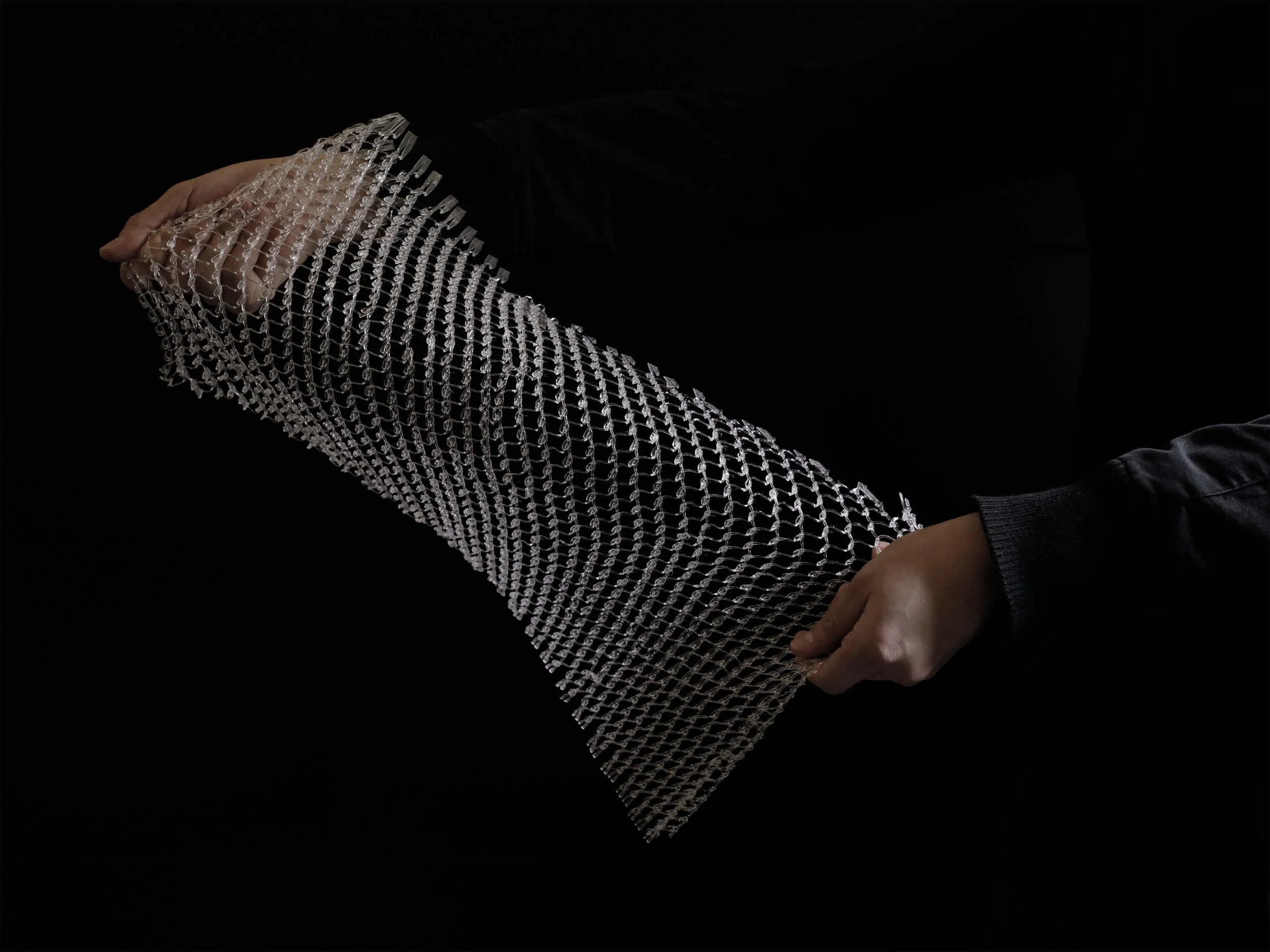

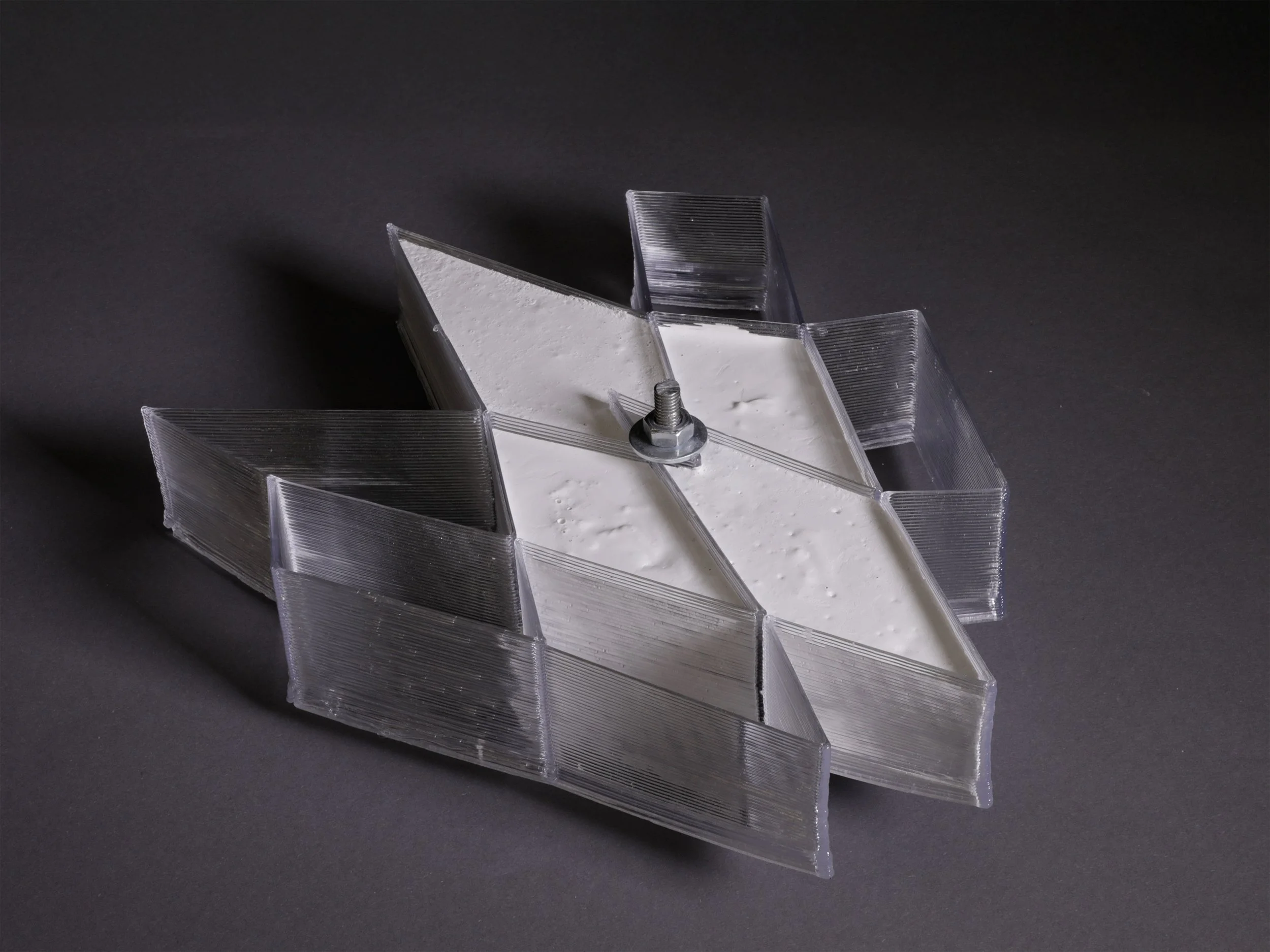

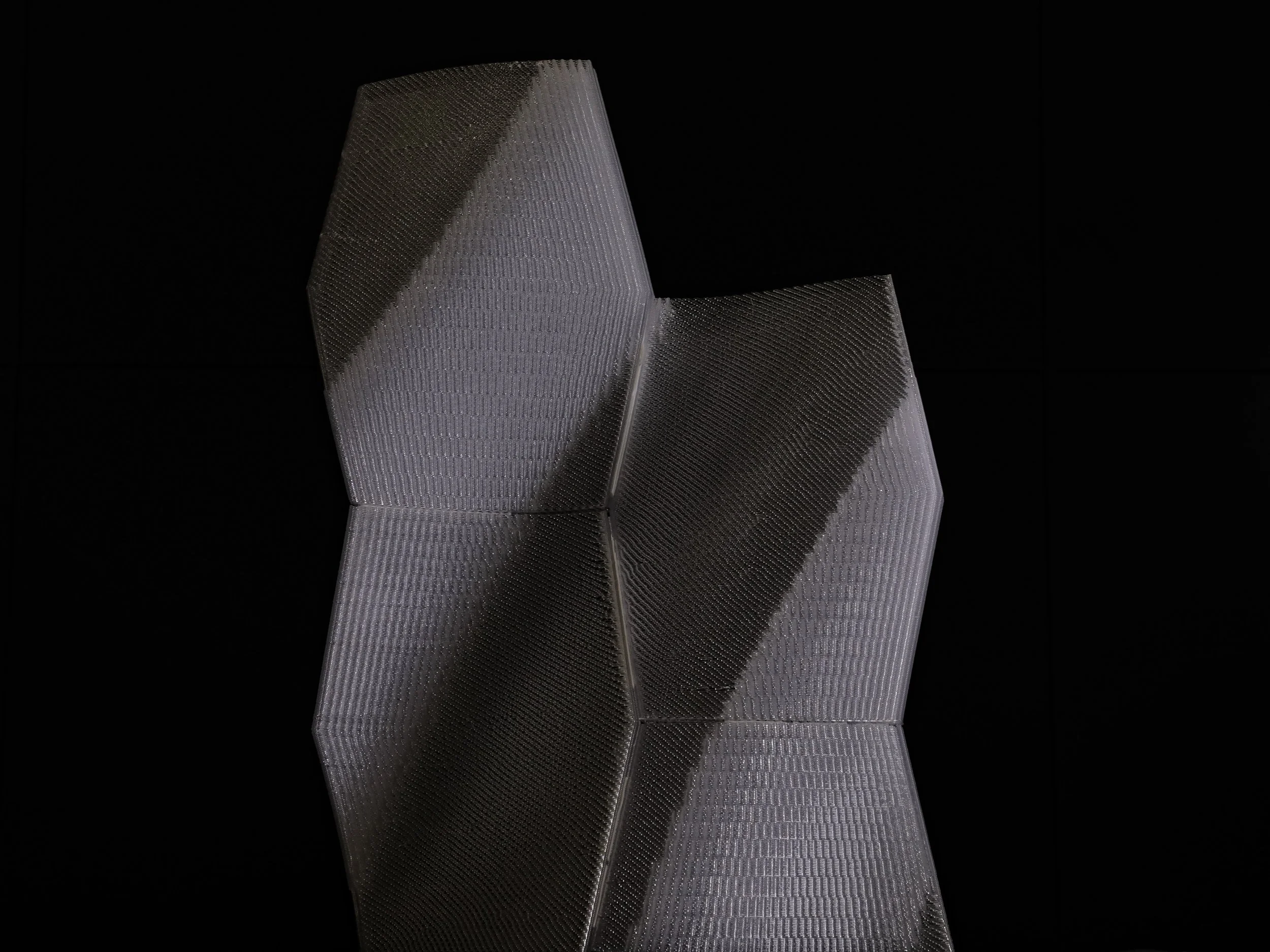

Key investigations include non-planar 3D printing, the use of flexible materials, and controlled toolpath manipulations to differentiate sparse regions from dense, structurally active zones. Emphasis is placed on understanding how toolpath logic and robotic motion can be used to encode performance gradients directly into printed facade elements.

As a precursor to Mini-HC3DP, the course establishes foundational knowledge in robotic additive manufacturing for envelope-scale applications. Mini Facade introduces students to fabrication-aware design workflows that position robotic 3D printing not as a representational technique, but as a core driver of architectural performance and material efficiency.

-

Artemis Maneka, Beril Önalan, Carlos Wilkening, Chengyuan Wei, Evgenia Angelaki, Foteini Salveridou, Guillaume Jami, Ilaria Giacomini, Ko Tsuruta, Lena Kitani, Liya Sunny Anthraper, Pascal Bach, Simon Griffioen, Soni Pryank, Wei-Ting Chen, Yen Fen Chan

-

-