Prōtóplasto

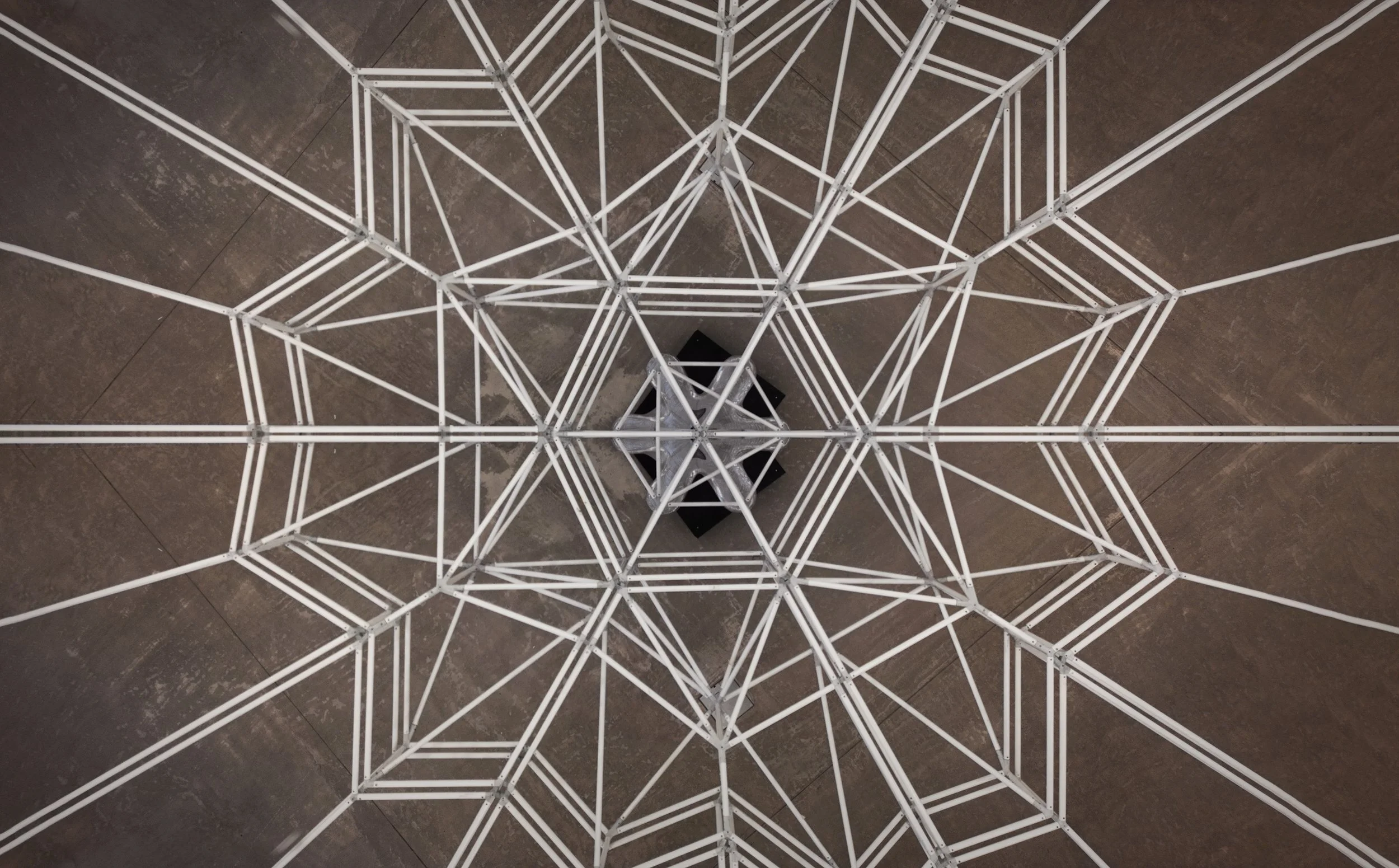

Prōtóplasto is an ultralight media installation exhibited at the innovation hub “Futurama” in Aargau, Switzerland. It is created with a novel constructive system pairing two new technologies: an innovative 3D printing method for polymers with very high build-up rates, which are similar to concrete extrusion, and 3D printed connections whose bespoke geometry enables support-free self-interlocking assembly of modular components. The word Prōtóplasto stems from the Greek word “πρωτόπλαστος” (prōtóplastos) meaning “the first formed”.

Prōtóplasto aims to introduce a new perspective on the use of plastics in architecture. The exemplary structure leverages multiple digital fabrication technologies in order to achieve moldless and waste-free construction. Protoplasto is designed entirely with custom computational tools that establish design and fabrication relations of its subparts, allowing the designer to adapt its form to different settings and locations.

Hollow-Core 3D printed columns

The pavilion features a modular arrangement of mushroom columns covering an area of 65 square meters with a specific weight of only 3.8kg/m2. Its columns are fabricated using an innovative 3D printing method known as Hollow-Core 3D Printing (HC3DP), which extrudes large tubular beads rather than solid ones. This novel approach has multiple advantages as it not only significantly increases the possible built-up rates,it does so by reducing material consumption and increasing the transparency of the print. The tubular geometry of the beads is made possible with the use of a custom nozzle and the introduction of positive air pressure. The nozzle splits and forms the molten plastic into a thin-walled bead around an empty core. Compressed air inflates the hollow bead and prevents it from collapsing while the material cools below the glass transition temperature. Thus, HC3DP pushes polymer 3D printing to an architectural-relevant scale, as a printed layer ranges from 10-24 mm while the build-up rate is comparable to concrete 3D printing. This technique allows for the production of 2.2-meter-tall columns in approximately 5 hours, using only 20 kg of material. When compared to traditional pellet extrusion systems that produce solid beads, HC3DP offers up to an 80% reduction in material use, showcasing significant efficiency and sustainability.

The foundation of these columns includes custom concrete footings that are cast using HC3DP formwork. This approach not only ensures stability but also extends the distinctive texture of the HC3DP columns to the base, creating a cohesive visual effect throughout the pavilion’s structure.

-

Total area: 65 sqm

Total weight: 250kg

Three 2.2m tall HC columns

Print time: 5h per column

291 connections in PA12

Two joint typologies

535 glass fibre rods

On-site assembly time: 12h

-

-

-

Eleni Alexi, Adam Anouar, Ana Ascic, Keng Chia Chang, Xue Chen, Po Yen Chen, Ahmed Elmeraghy, Caitlin Emily Gallagher, Yixiao Huang, Yi Hsiu Hung, Chenming Jiang, Lihin Karunadhipathi, Joseph Kenny, Man Ki Ian Law, Pedro Lopez Moldano, Nijat Mahamaliyev, Abhipsa Pal, Carl Pantos Conquilla, Etienne Pavoncello, Huang Su, Lee Yo Cheng, Zhuo Zhang

-