Mycelium Bound Composites

Mycelium-bound composites (MBCs) represent a new generation of bio-based building materials that combine low embodied energy, local producibility, and full biodegradability. Cultivated from fungal mycelium growing within agricultural by-products, MBCs offer excellent thermal and acoustic performance and can be produced without resource-intensive manufacturing. Their broader architectural adoption, however, is limited by two core challenges: low structural capacity and the difficulty of shaping the material into precise, performance-driven geometries.

This research investigates how computational design and digital fabrication can expand the architectural viability of MBCs across multiple fabrication pathways. Early explorations focused on CNC milling of pre-grown substrate blocks, evaluating how subtractive shaping can generate bespoke geometries and surface textures while maintaining material integrity. Parallel studies examined CNC machining after the growth cycle, allowing refinement of components once the biological process is halted. These investigations provided first insights into how MBCs respond to conventional tooling and how machining parameters influence surface quality, density, and failure behavior.

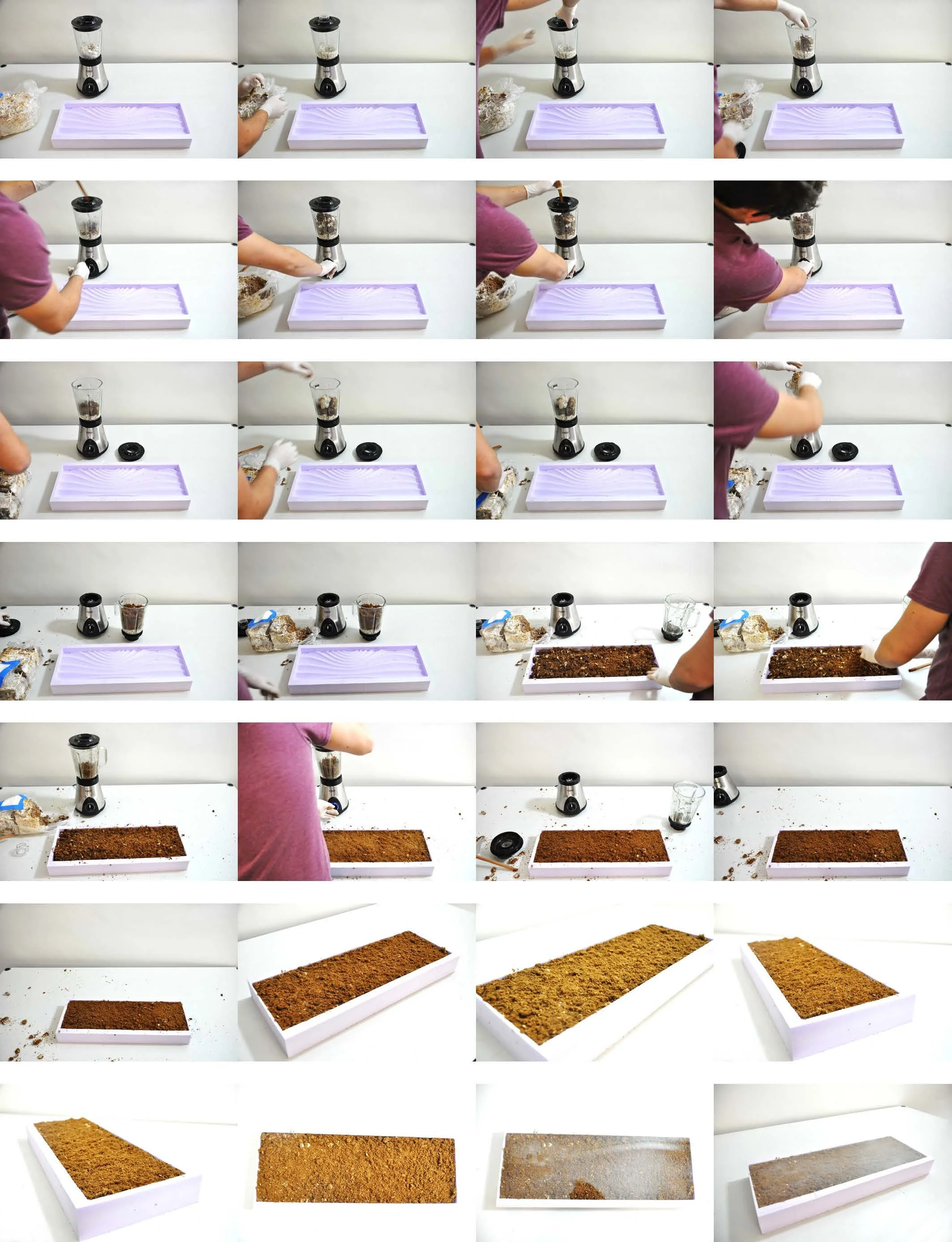

Complementing these subtractive methods, the research explores additive and hybrid formwork strategies, including 3D-printed polymer formwork that enables complex internal geometries, integrated channels, and controlled areas of permeability. These approaches test how different polymers, dissolution behaviors, and formwork geometries affect growth performance, consolidation, and the final material properties of MBCs.

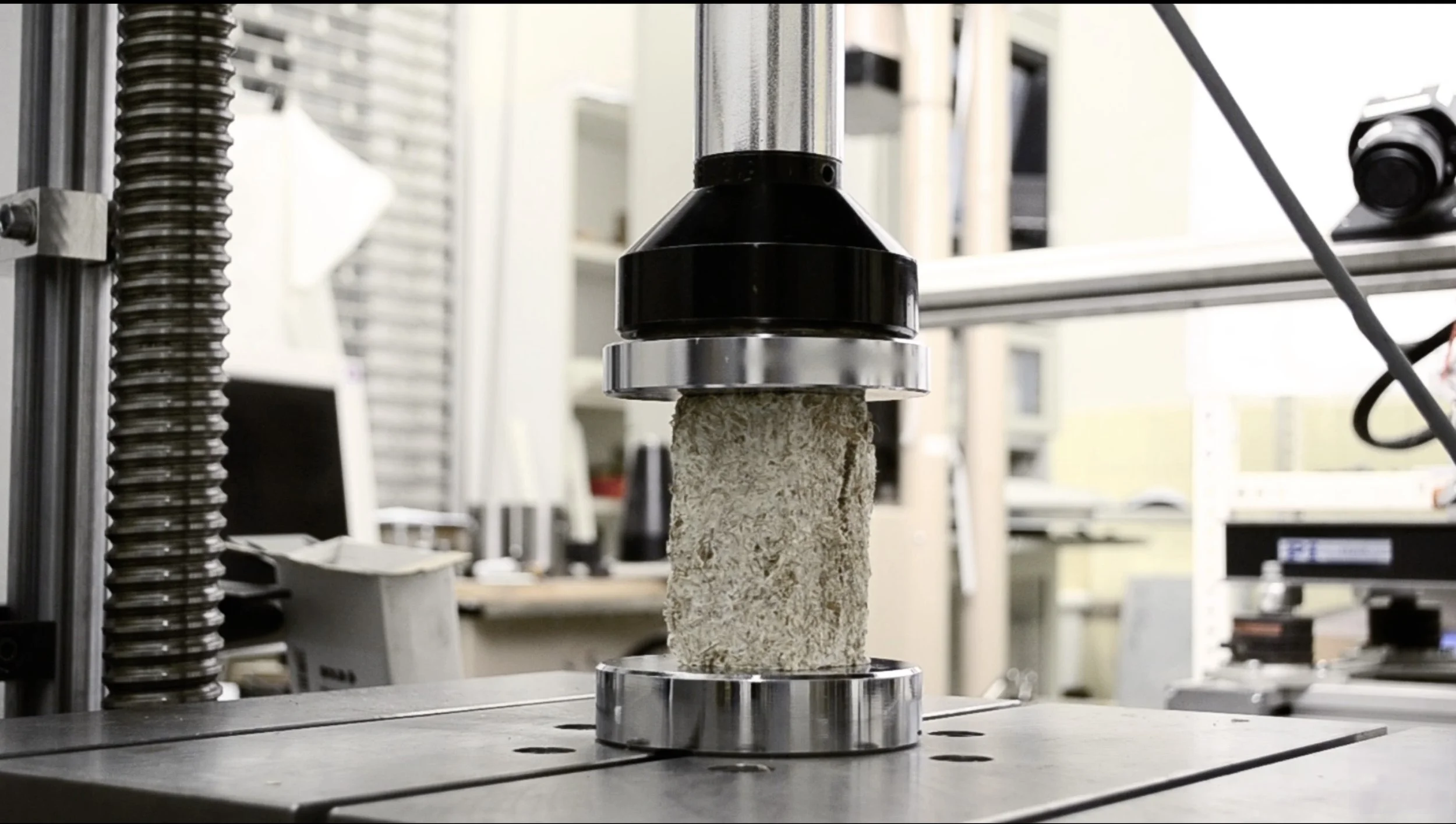

To evaluate architectural applicability, the work also conducts early compression testing across different substrates and growth conditions. These results help establish the mechanical envelope of MBCs and identify design strategies—such as curvature, ribbing, or shell geometries, that can compensate for limited compressive strength.

Together, these investigations outline a multi-faceted research trajectory that couples biological growth processes with computational design and digital fabrication. By examining both subtractive and additive workflows and grounding them in material testing, this research defines a framework for producing bespoke, materially efficient, and biodegradable components. Ultimately, it positions MBCs as a viable contributor to sustainable, low-impact construction ecologies.