Timber Canopy

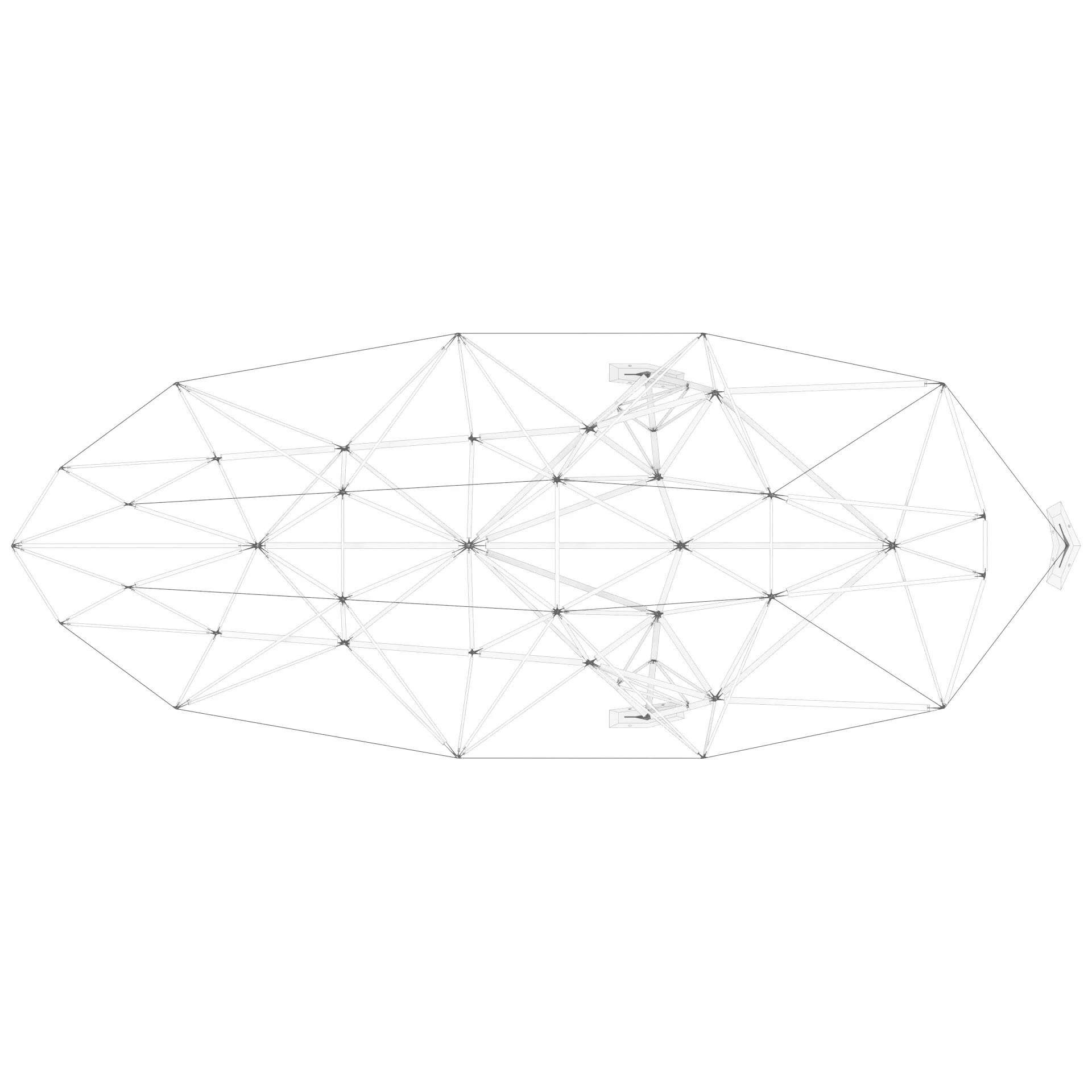

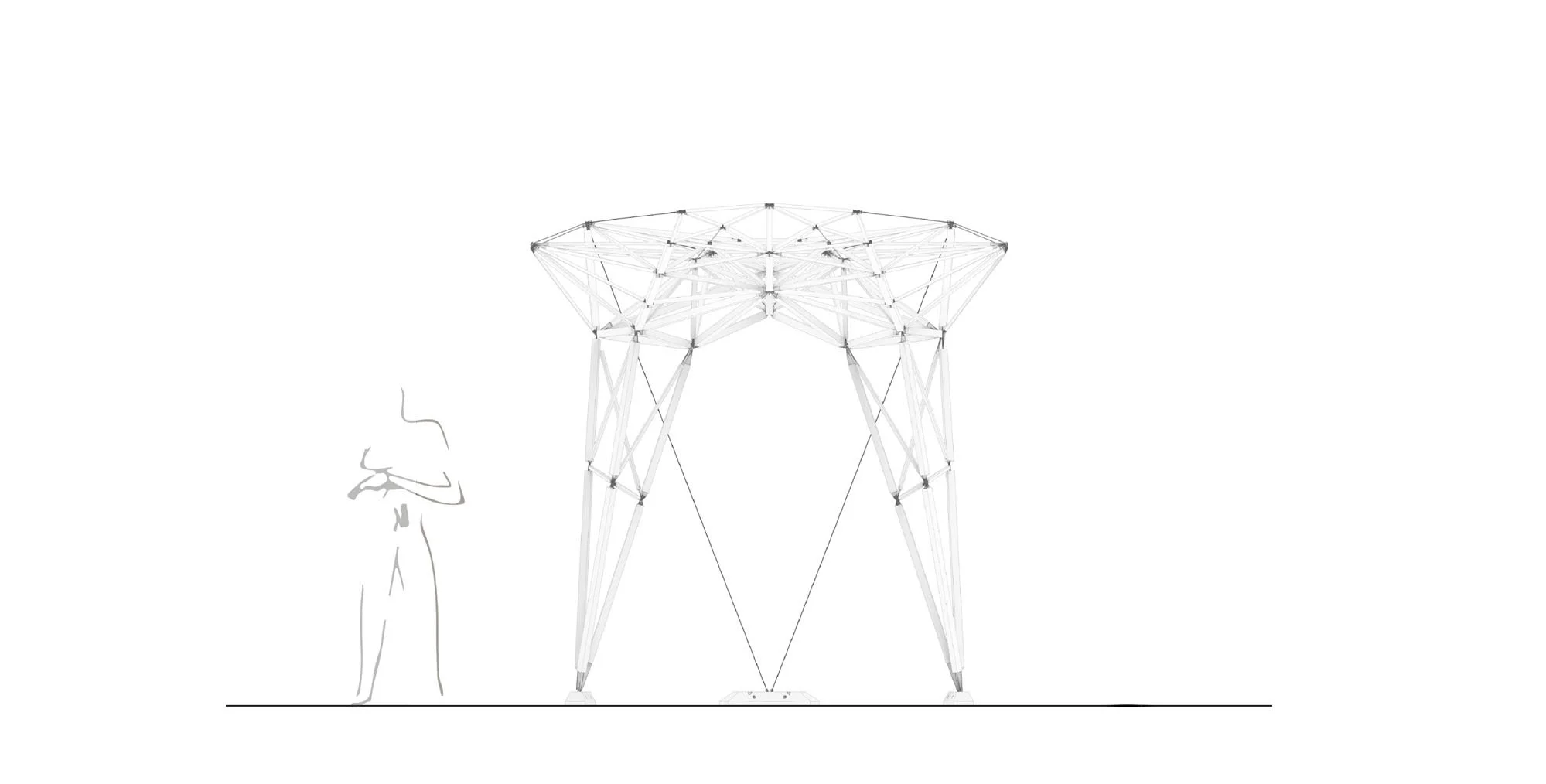

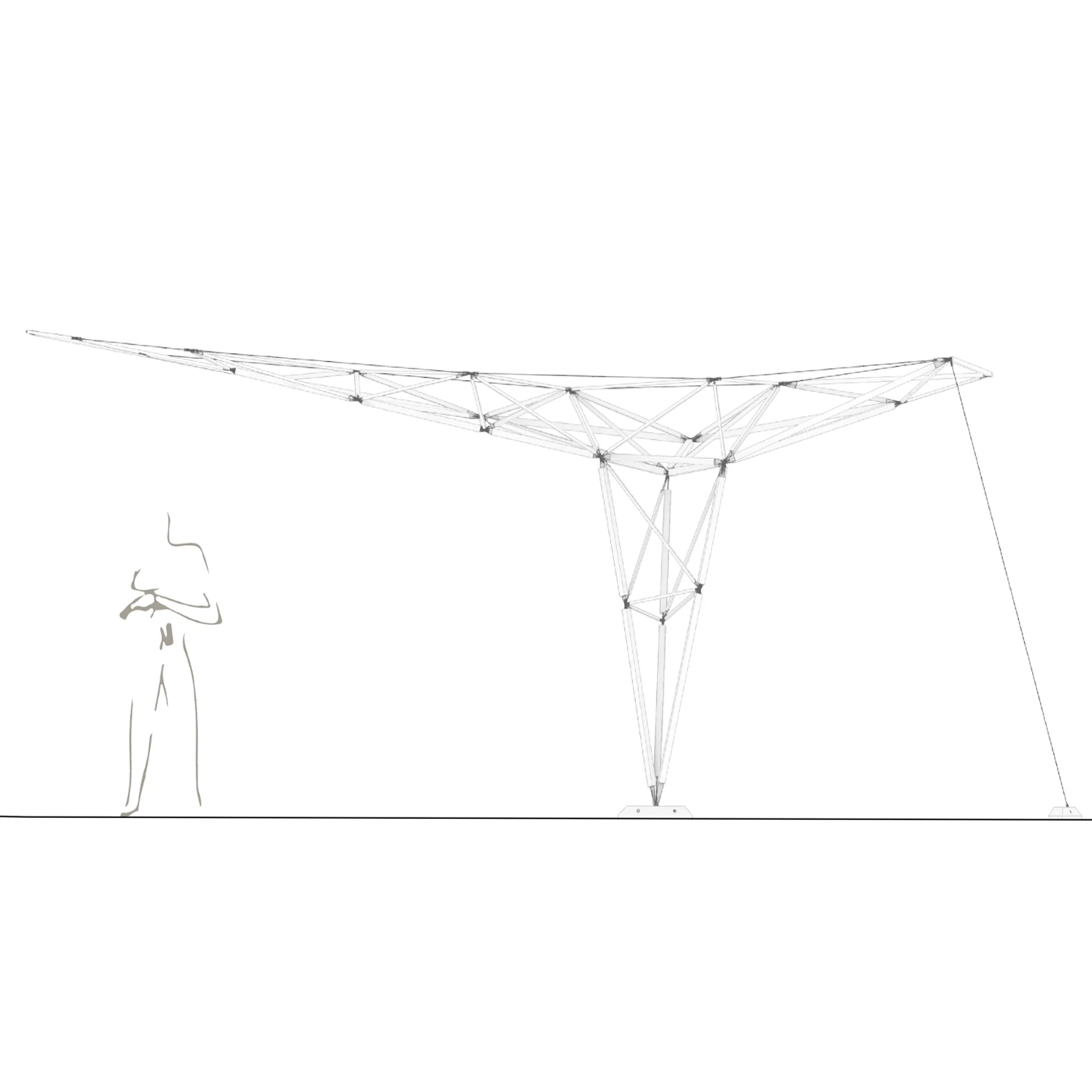

This thesis project investigates how common desktop FDM printers can be leveraged to prototype bespoke structural connections for lightweight timber assemblies. Timber Canopy explores how inexpensive polymer joints, when computationally tailored, can enable structural configurations, exemplified by a 4-meter cantilever formed through optimized connection geometry and member hierarchy.

A custom design workflow introduces students to mesh-based generative grammars that encode structural logic directly into joint morphology. Starting from a line network, participants classify primary and secondary members and annotate tension- and compression-dominated elements. Collision-based scaling rules then determine local cross-sections, connection reach, and reinforcement intensity. This hierarchical system produces adaptable thickening, integrated compression plates, and cable-based tension reinforcement, while mesh subdivision provides force-flow-oriented surface articulation.

The pedagogical value lies in demonstrating how a single algorithmic pipeline can output all fabrication data, from linear-element matrices to joint geometries and assembly information. Students also implement print-orientation optimization to minimize material use and production time.

The resulting demonstrator canopy consisted of 157 timber members and 47 unique printed connections, illustrating both the diversity of the method and the central lesson of the module: even low-strength, low-cost materials can perform structurally when geometry, hierarchy, and fabrication constraints are intelligently integrated.

-

Alexander Enz

-

Marirena Kladeftira and Matthias Leschok

-

-