Smart Formwork

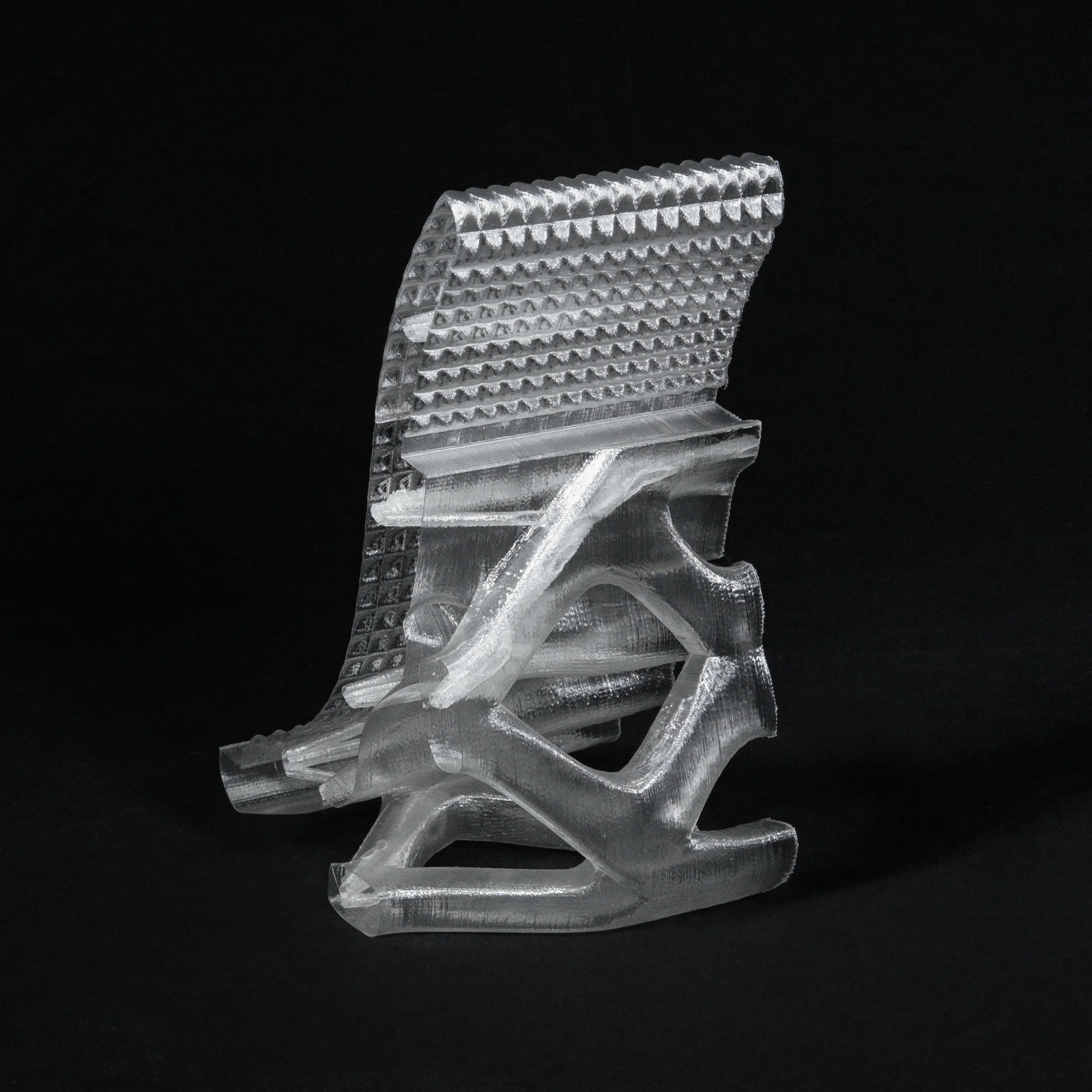

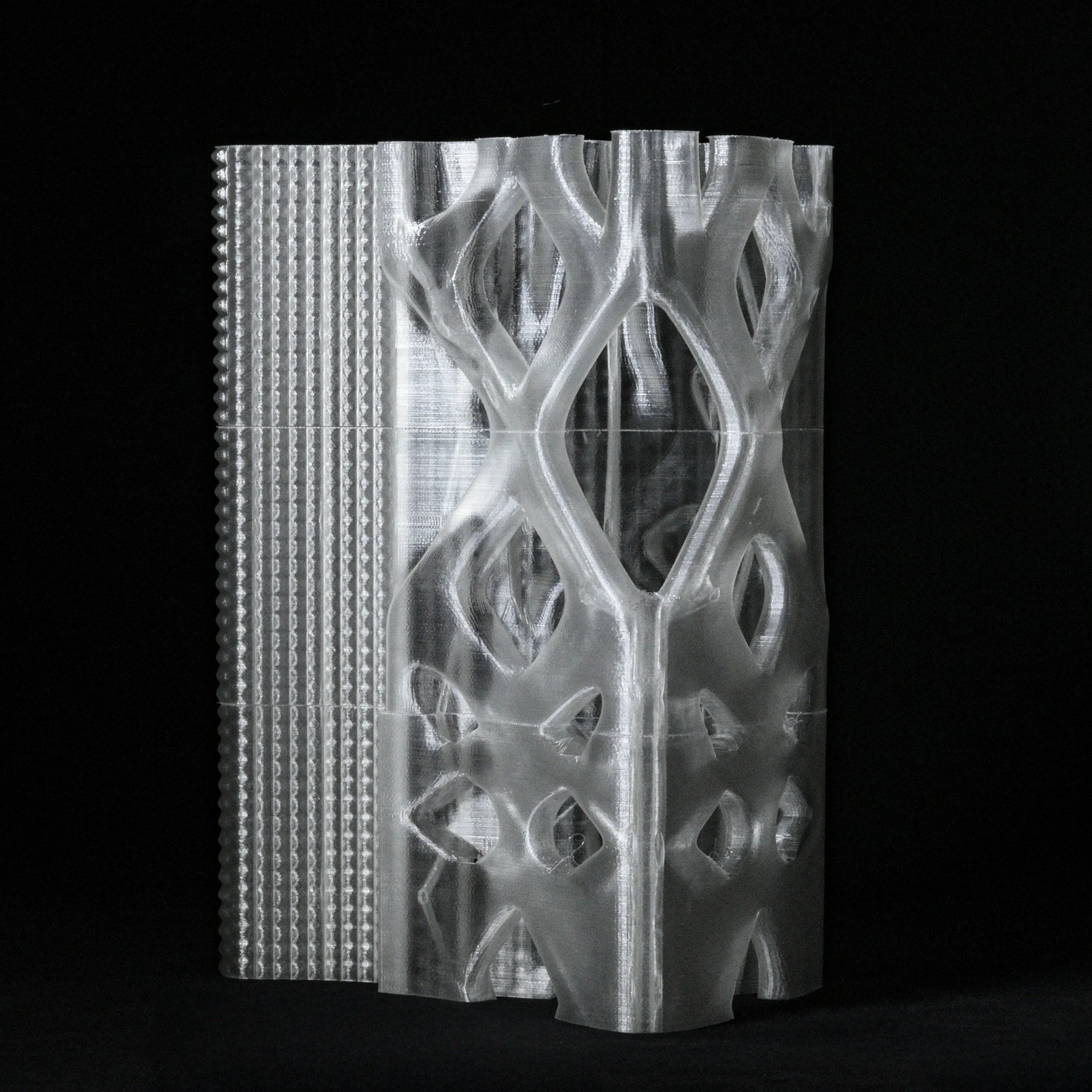

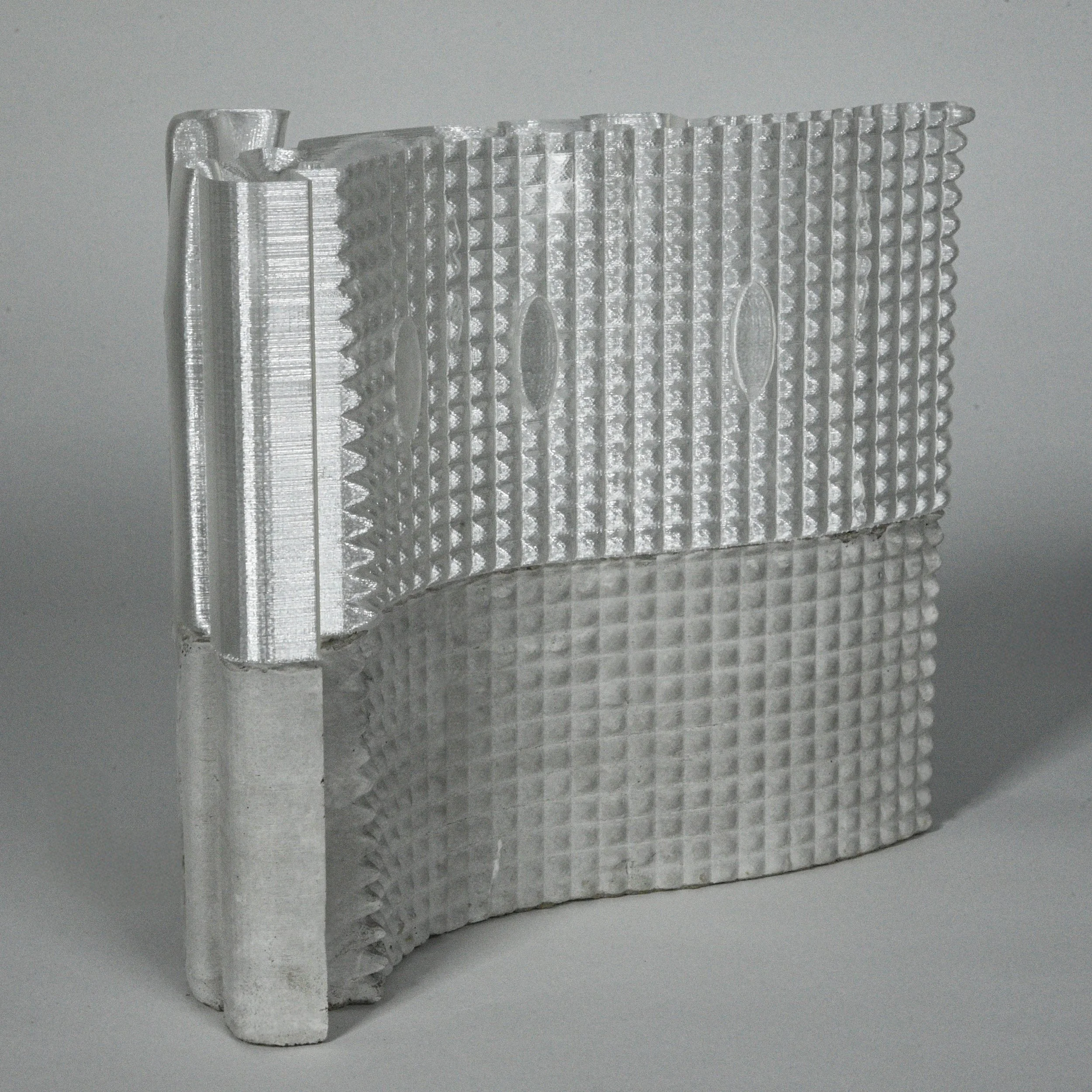

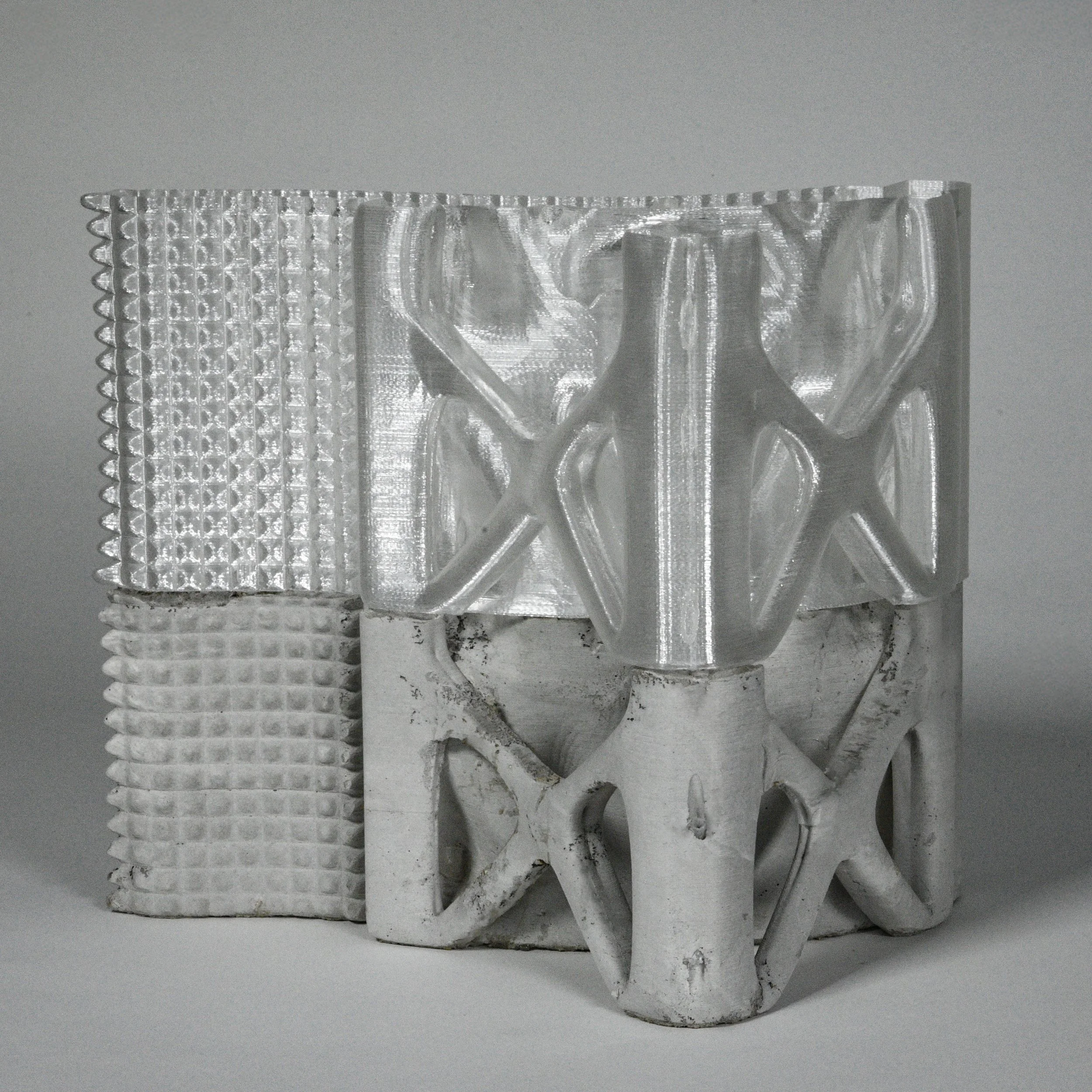

Smart Formwork is a six-week intensive design module in the MAS ETH DFAB program (2017–2018), in which students design and fabricate ultra-thin 3D-printed formwork for bespoke concrete components. Working in groups of two to three, participants explore the full workflow from computational design to physical prototyping using off-the-shelf FDM printers and ultra-high-performance fiber-reinforced concrete.

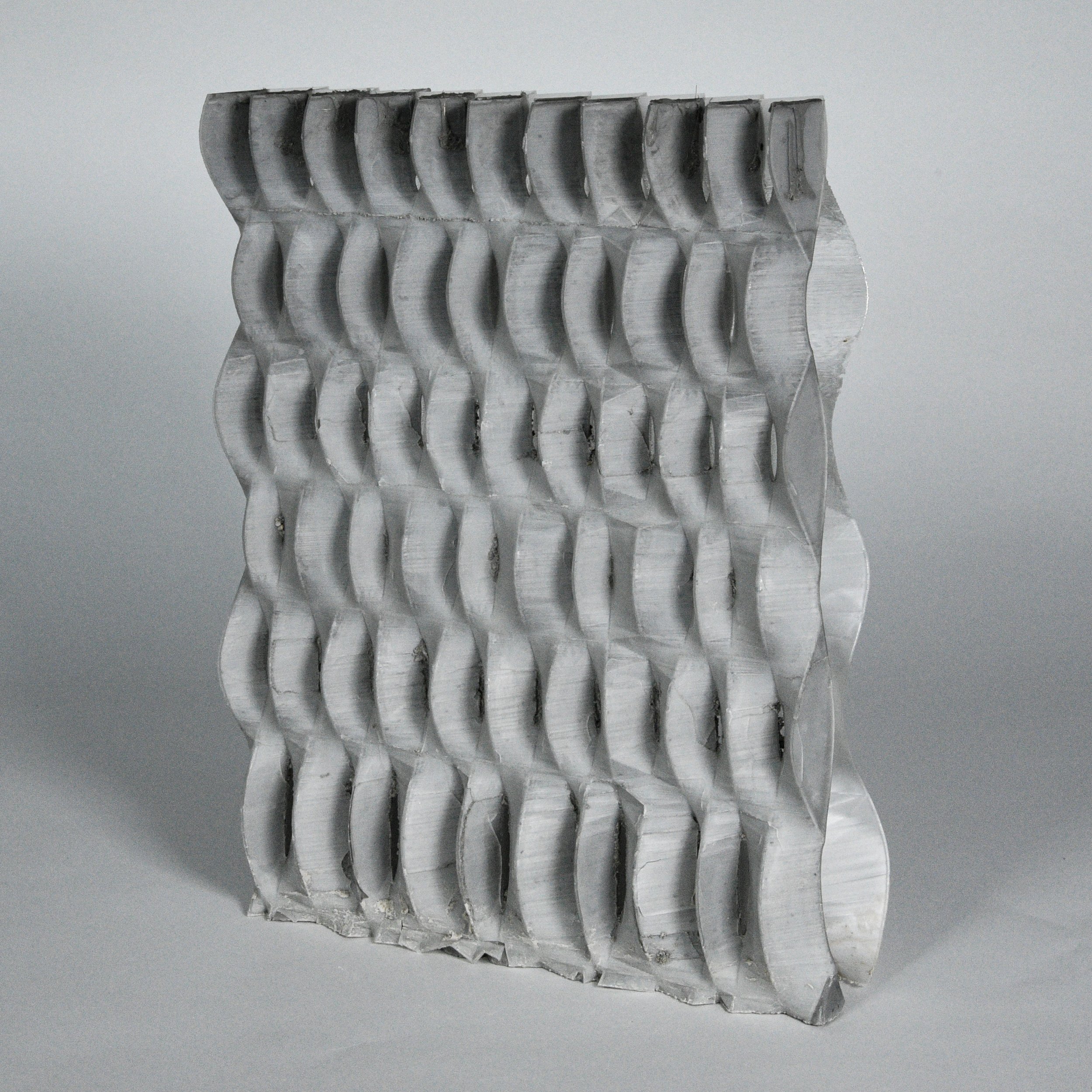

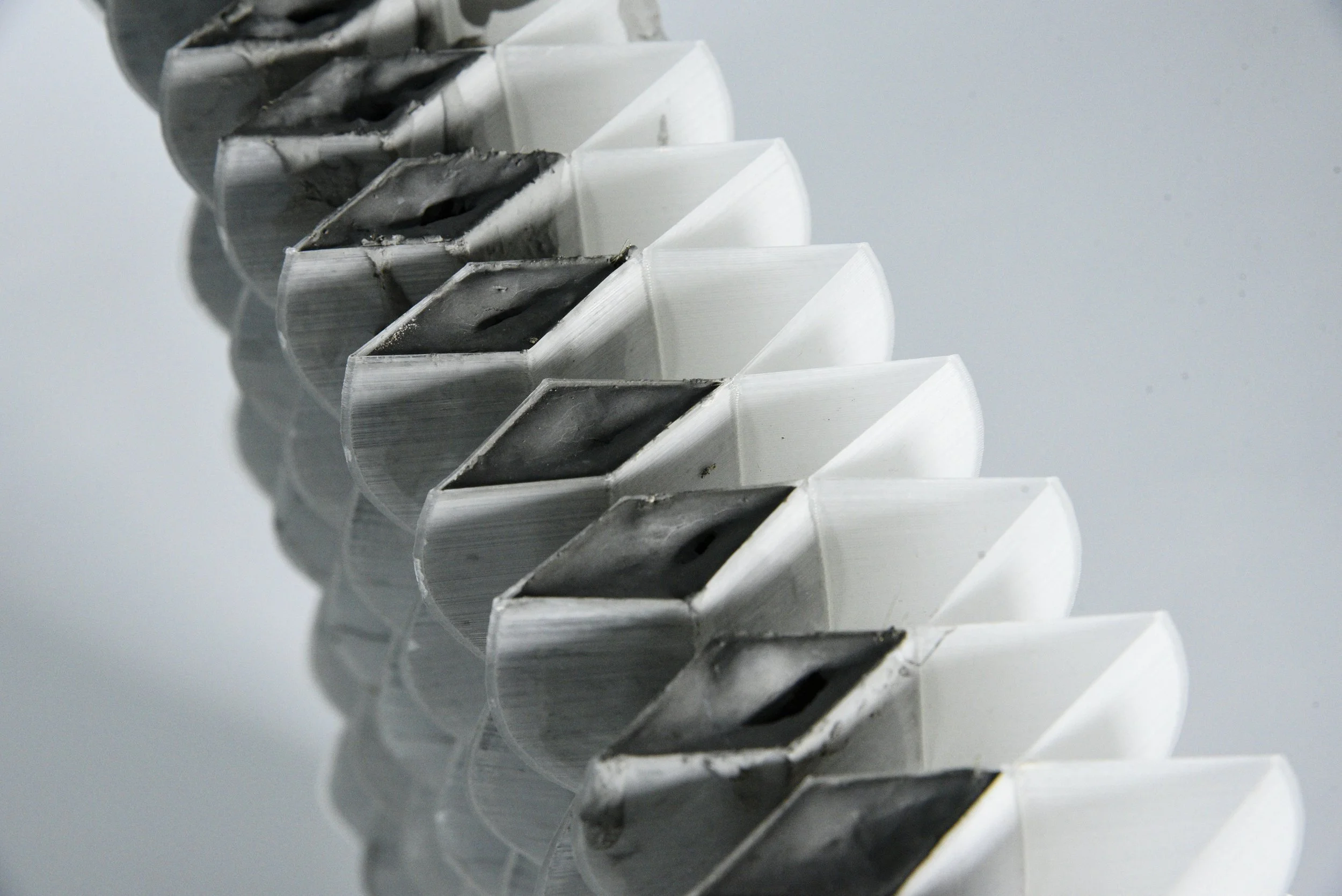

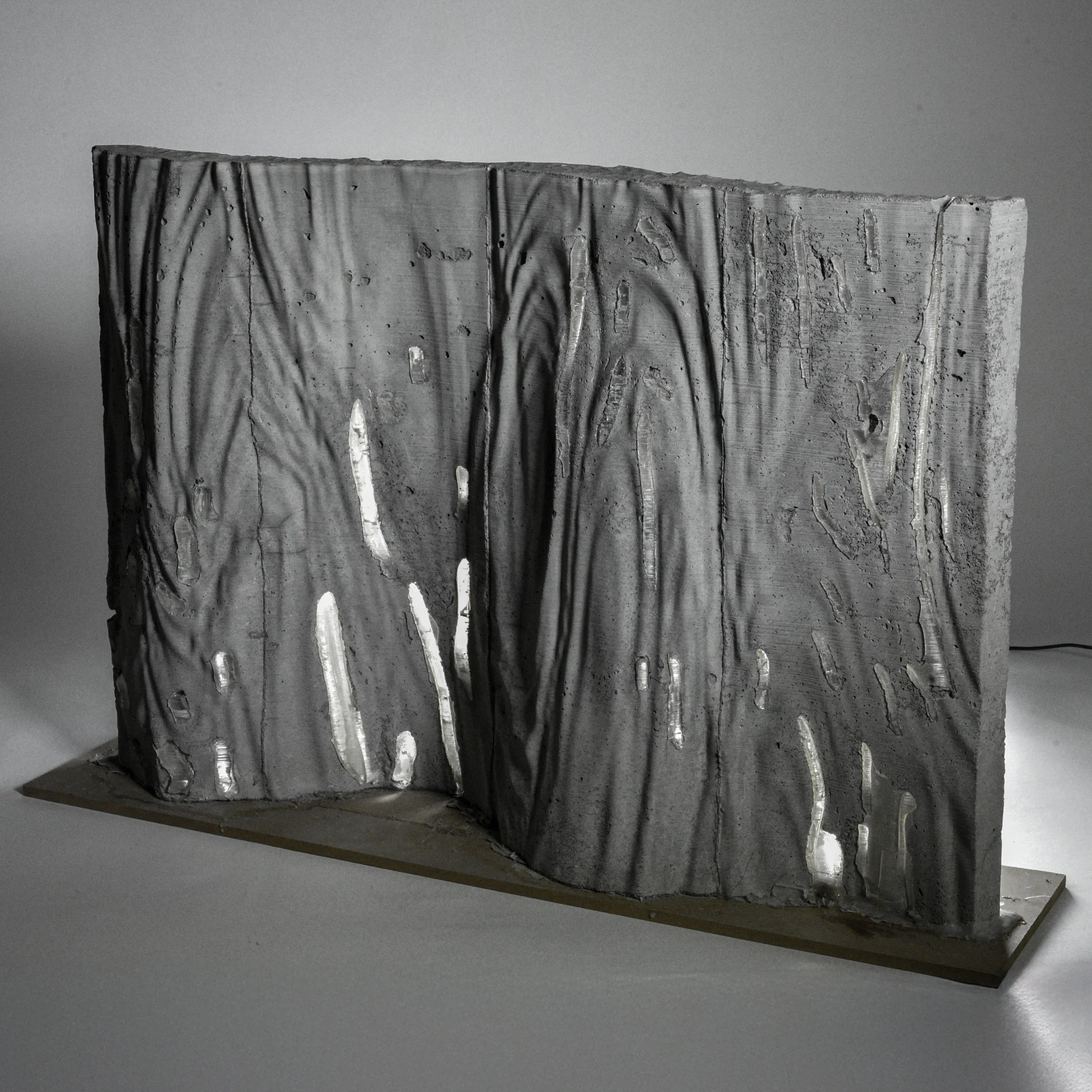

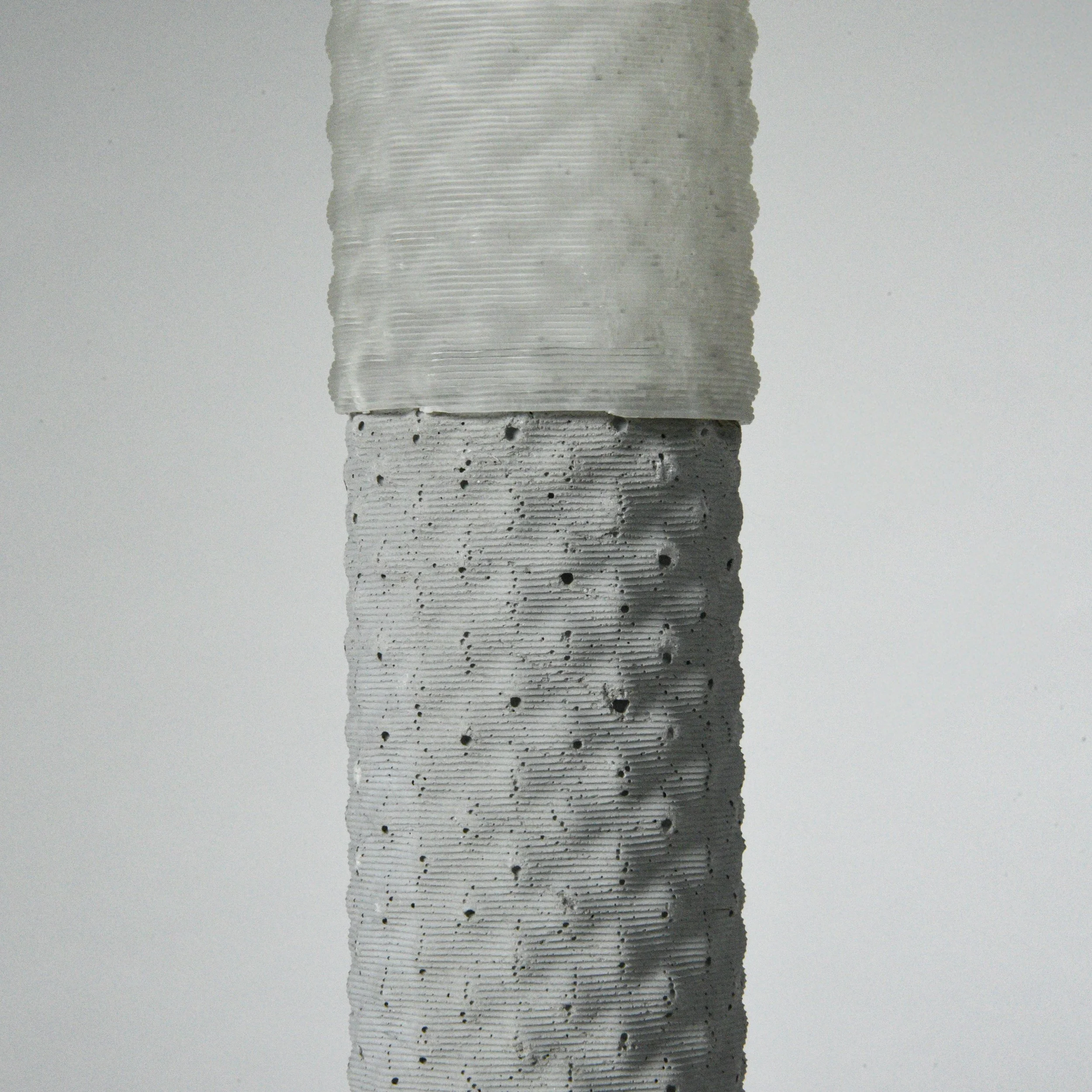

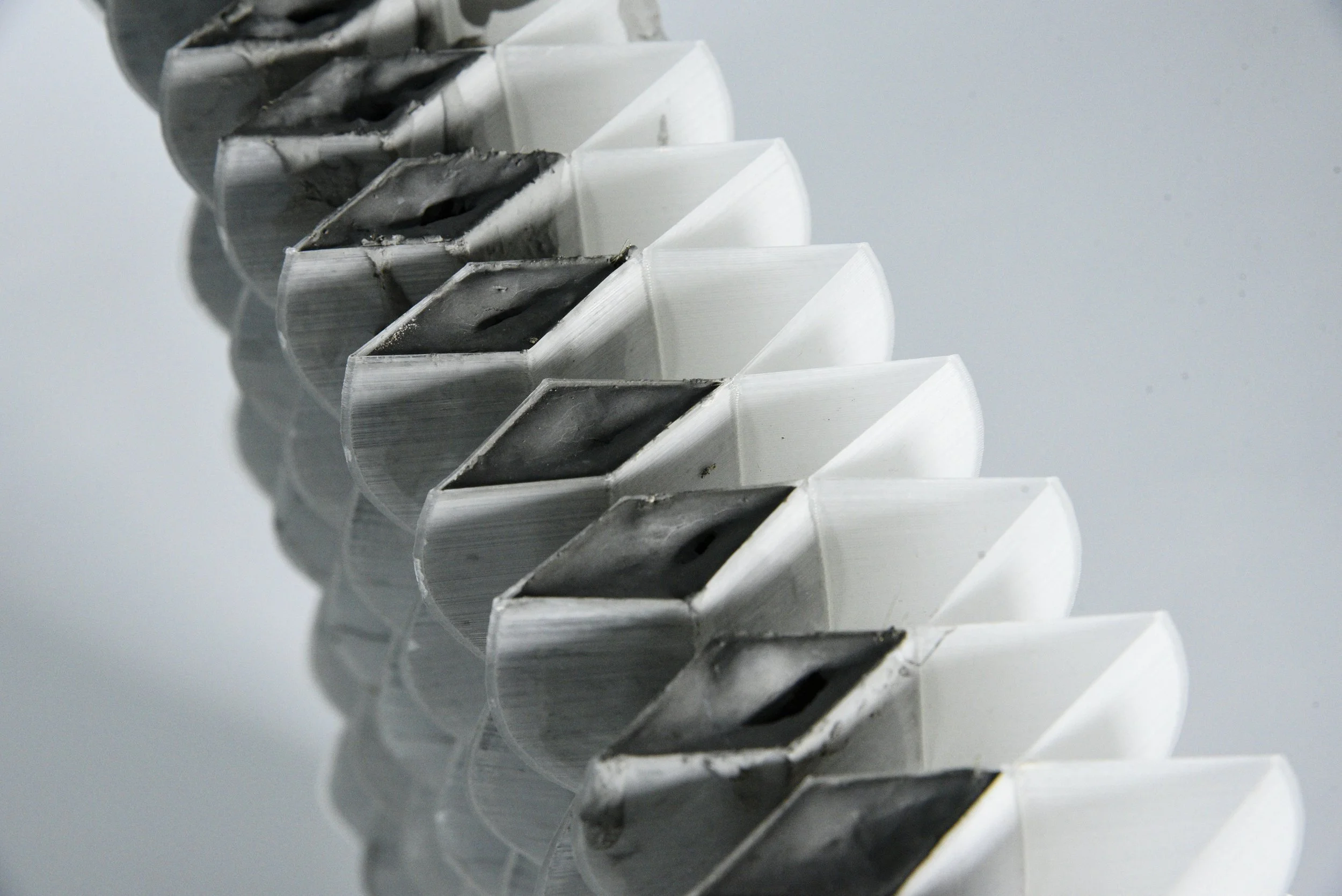

The course introduces students to the fabrication constraints of extrusion-based 3D printing and challenges them to push the limits of sub-millimeter-thick formwork. Because such thin prints are inherently fragile, students investigate strategies to stiffen their formwork through geometric and textural variation. These explorations reveal how surface patterning influences rigidity, casting performance, and overall build quality.

Design outcomes range widely, from stay-in-place façade systems and bespoke column formwork to segmented precast roof elements. Through iterative prototyping and concrete casting, students gain hands-on experience with material behavior, structural performance, and digital-to-physical translation. By the end of the module, they develop a refined understanding of how computational design, 3D printing, and concrete fabrication can converge to produce lightweight, highly customized architectural elements.

-

Alexander Enz, Angela Yoo, Fernando Cena, Francisco Regalado, Frank Lin, Georgia Chousou, Haruna Okawa, Ioanna Mitroupolou, Jetana Ruangjun, Jun Su, Matteo Lomaglio, Moon Young Jeong, Nizar Taha, Rafael Pastrana, Sahar Barzani, Yao Wang, Zong-Ru Wu.

-

Andrei Jipa and Matthias Leschok

-

-