Aerogel Infused 3DP Facade

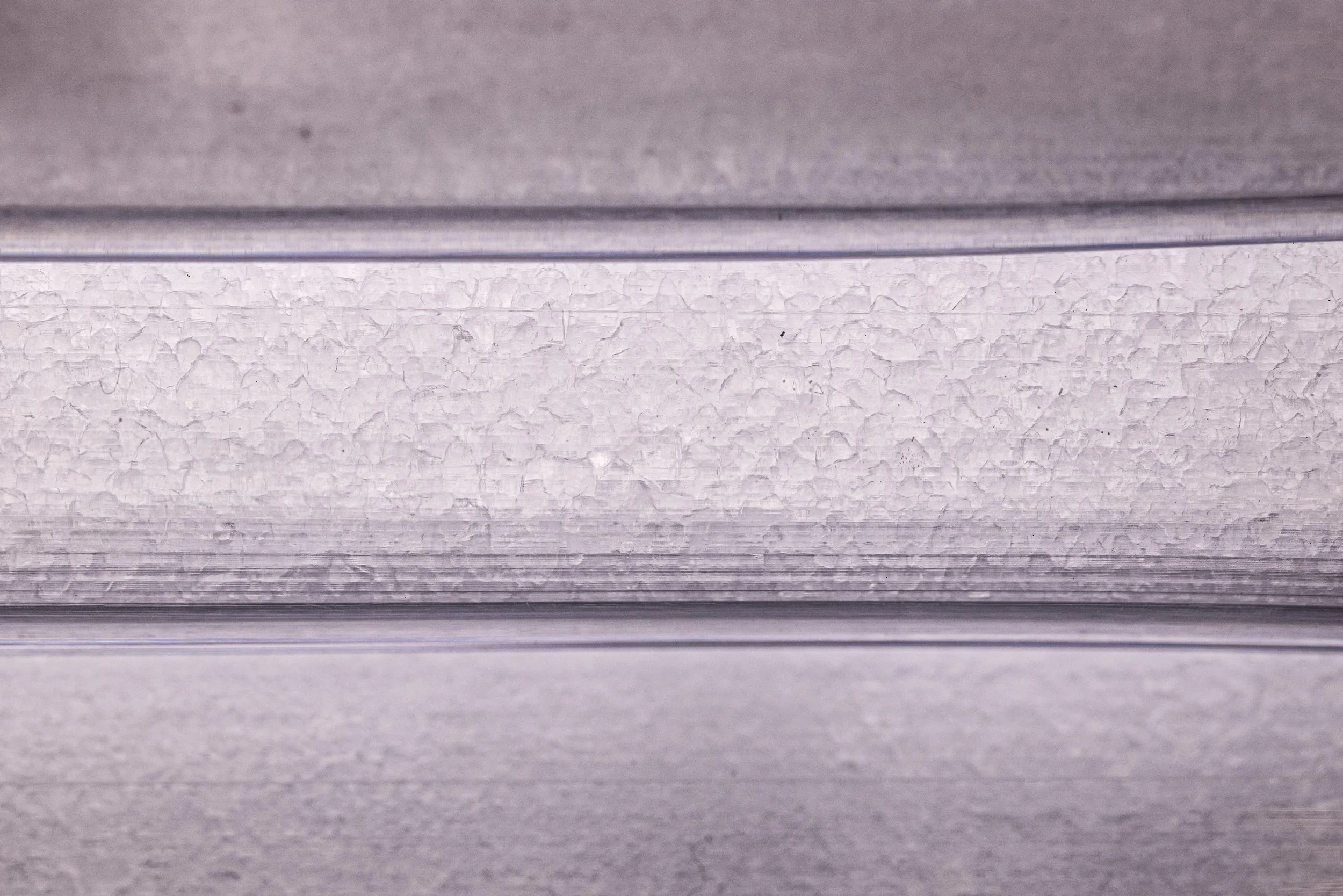

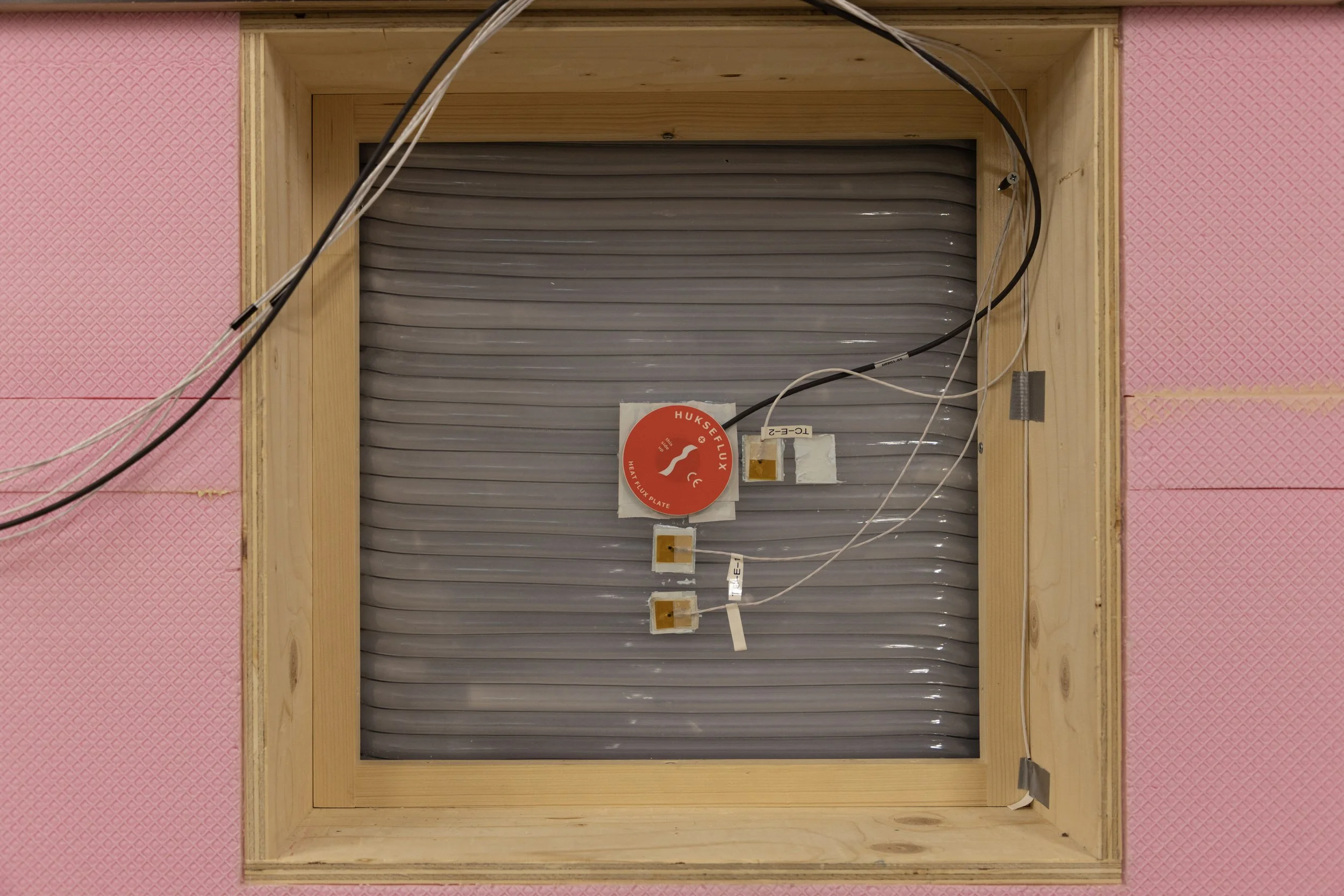

A novel constructive system is introduced for the fabrication of ultra-lightweight, highly insulating, and translucent façade elements. The approach combines a recently developed polymer-based 3D-printing process capable of producing hollow extruded beads with the subsequent injection of aerogel as an insulating infill. This work emerges from interdisciplinary research conducted within the NCCR Digital Fabrication and advances ongoing investigations into additive manufacturing for façade applications.

Additive manufacturing enables a high degree of geometric freedom, permitting complex morphologies and surface textures that are difficult or impossible to achieve with conventional methods. In façade construction, 3D printing offers the potential to reduce both embodied energy and material consumption through targeted material placement, functional integration, and the capacity for site-specific design. Tailoring elements to local climatic conditions further enhances thermal and environmental performance.

The proposed system is conceived as fully reversible: aerogel is injected into the hollow-core printed elements during fabrication and can be removed at end of life, allowing reuse of the aerogel granulate and recycling of the polymer component. The presented prototype has a thickness of 7.5 cm, a U-value of 0.86 W/m²K, and contains 600 g of aerogel. Its construction comprises two aerogel-filled layers separated by an internal air cavity. With a weight of only 16 kg/m², of which 2.4 kg corresponds to aerogel, the HC3DP façade element achieves thermal performance comparable to a triple-glazed window while being approximately twice as light.

-

Print time: 1 m2/h

Layer height: 19 mm

Layer width: 25 mm

Panel depth: 70 mm

U-Value: 0.86 W/m2K

-

-

-

Dr. Valeria Piccioni, Dr. Ina Cheibas, Prof. Gramazio, Prof. Kohler, Prof. Schlueter, Prof. Dillenburger