Additive Archetypes

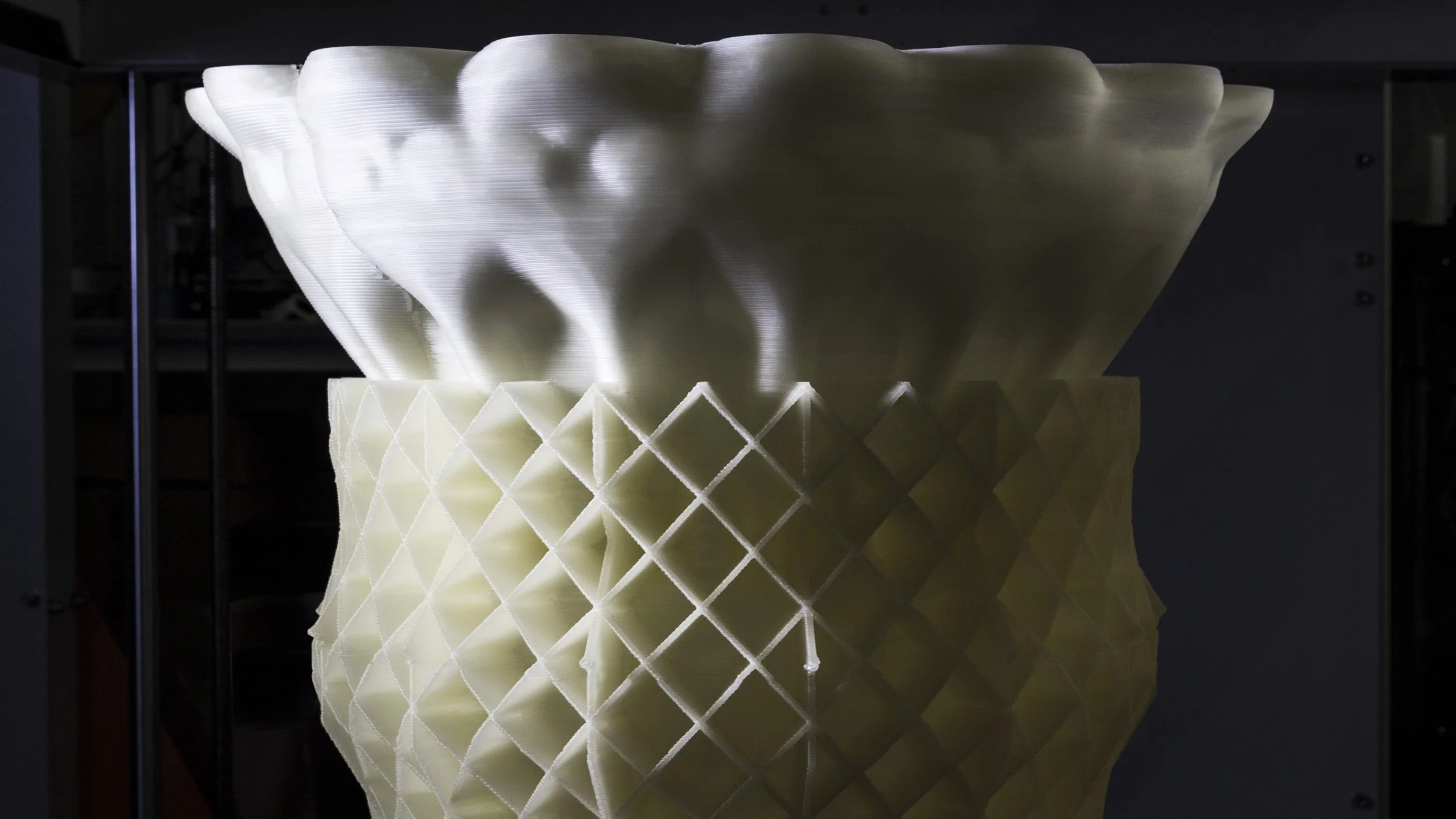

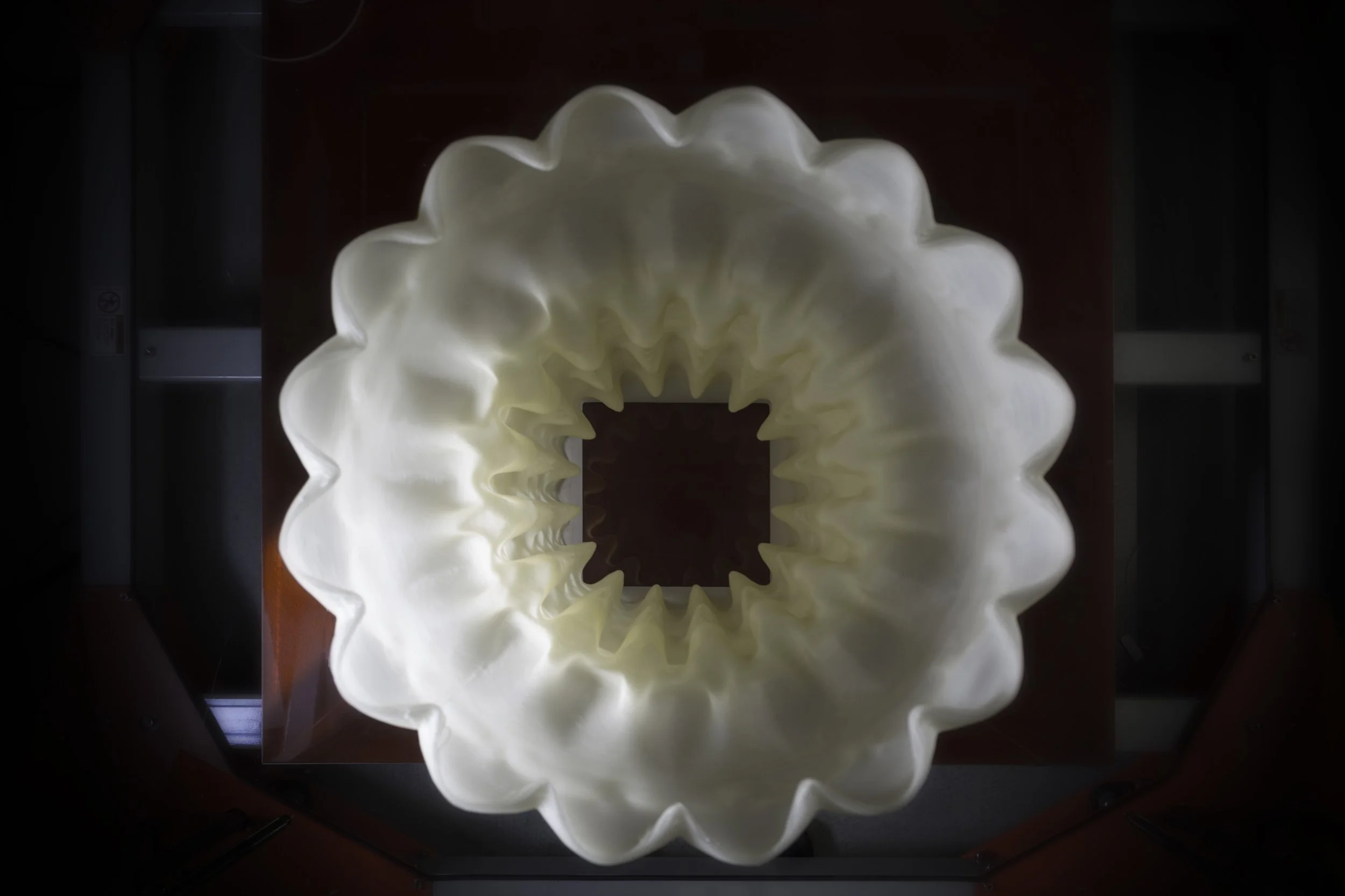

Additive Archetypes demonstrates how water-dissolvable, FDM-printed formwork can enable materially efficient, highly articulated concrete components. Developed from the research on dissolvable formwork, these prototypes are among the first large-scale concrete elements cast inside entirely water-soluble 3D-printed molds. The approach merges lightweight, biodegradable formwork with the geometric freedom of additive manufacturing, opening possibilities for ornamented, integrative, and structurally informed concrete parts.

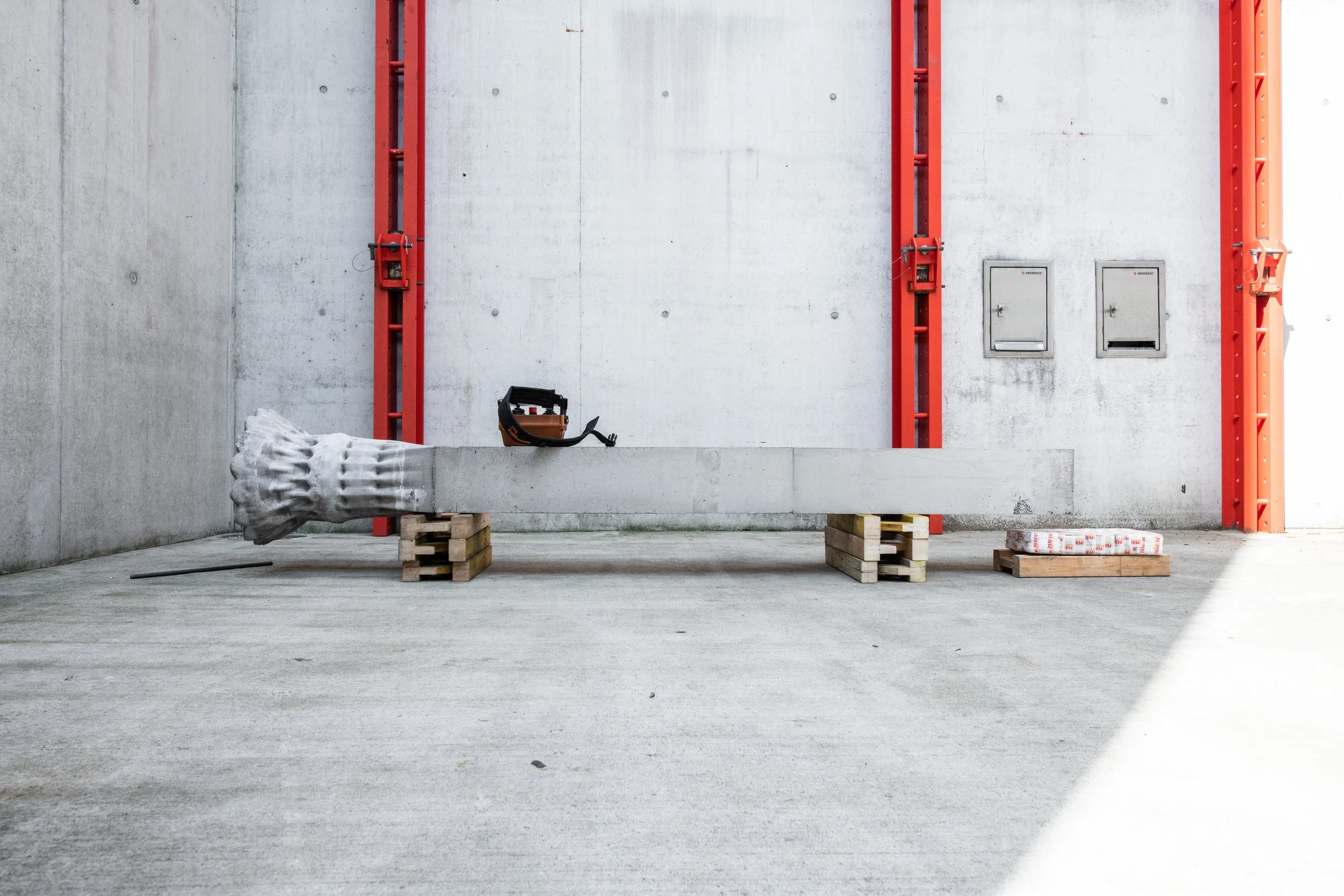

The demonstrator focuses on a 3-meter-tall column that combines standard formwork with a bespoke 3D-printed capital. Only 8 kg of printed formwork supported 250 kg of conventional formwork and withstood the pressure of 220 liters of concrete, illustrating the structural efficiency of the system. A custom line-subdivision procedure was used to generate a smooth transition from the square shaft to the ornamented capital, which also integrates a standard rebar cage to produce a fully load-bearing element.

Water-dissolvable formwork provides clear advantages over conventional FDM formwork removal: undercuts and internal cavities can be cast without mechanical break-out, and the formwork simply washes away after curing. The material is fully biodegradable and can be reclaimed for reuse if not dissolved. By combining standard systems with additively manufactured refinements, the project shows how complexity can be placed only where needed, reducing printing time, material use, and waste while expanding the architectural potential of 3D-printed formwork.

-

-

-

Dr. Valeria Piccioni, Dr. Ina Cheibas, Prof. Gramazio, Prof. Kohler, Prof. Schlueter, Prof. Dillenburger

-

FIXME

-

Julius Hatt and Girts Apskalns