Digital Bamboo Pavilion

The Digital Bamboo Pavilion investigates how a rapidly renewable bio-material can be transformed through computational design and digital fabrication. Bamboo, with its exceptional strength-to-weight ratio, forms the structural basis of the pavilion, while bespoke 3D-printed connectors enable unprecedented geometric freedom. Spanning more than 40 m² and weighing only 200 kg, the pavilion demonstrates how lightweight, high-performance architecture can emerge from the careful integration of natural materials and advanced fabrication methods.

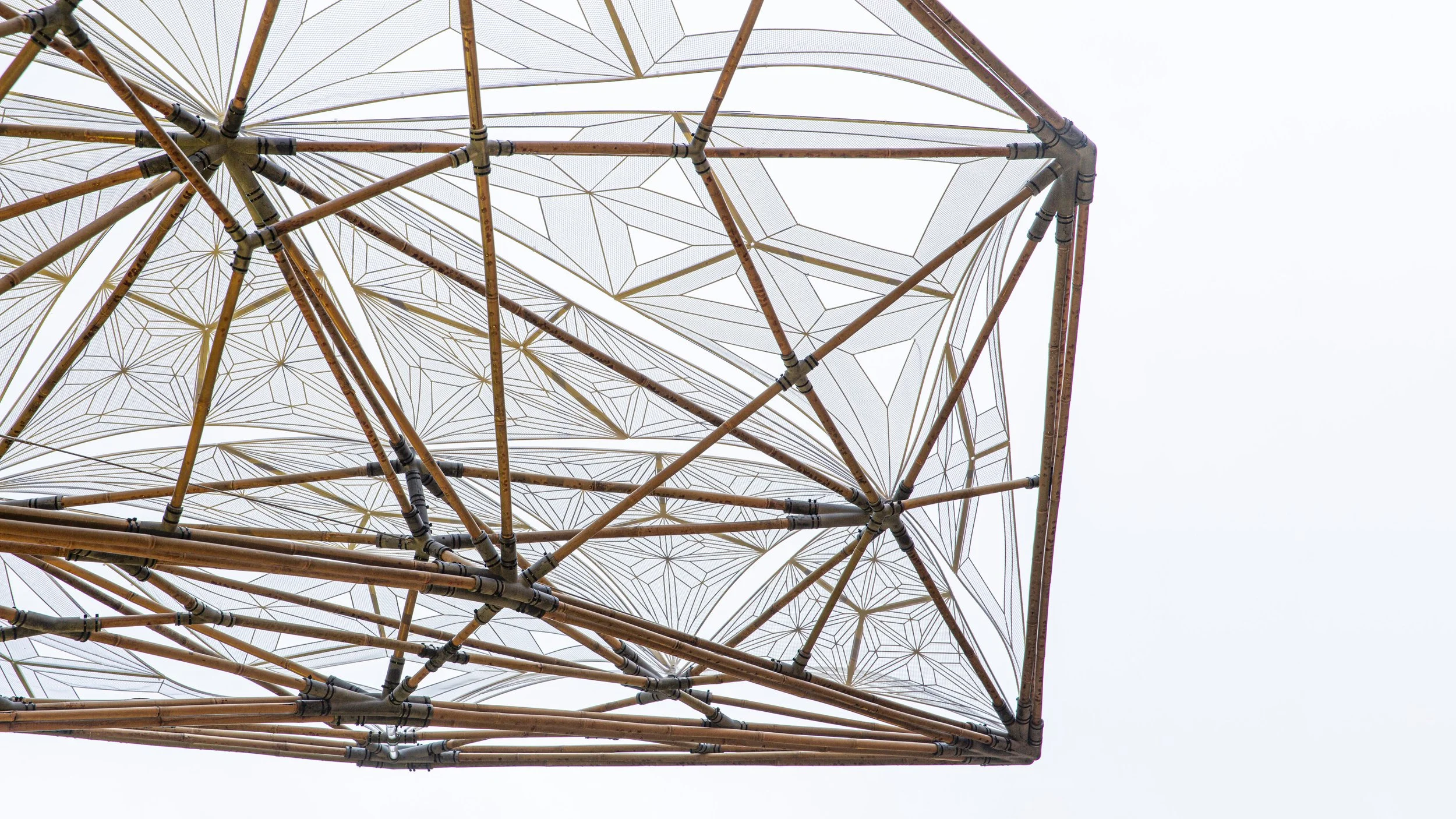

The spatial structure consists of over 900 bamboo elements arranged into a filigree truss system reinforced with post-tensioned cables. Its geometry was developed using custom form-finding tools that optimize load distribution and allow the pavilion to cantilever nearly five meters in three directions with minimal support. Computational design enabled both structural efficiency and formal exploration, resulting in a highly expressive, non-standard space frame that moves beyond conventional modular vocabularies.

A central innovation lies in the 380 bespoke connections manufactured through a hybrid method combining Multi Jet Fusion and Direct Metal Laser Sintering. These components encapsulate structural performance, assembly tolerances, and the inherent inhomogeneity of bamboo. Their intricate geometries integrate cable fittings, shading-panel interfaces, and automated labelling, while remaining materially efficient and cost-effective. The shading system itself is accomplished through a custom digital process in which recyclable UV-resistant thermoplastic is 3D-printed onto lightweight Lycra textile, locally stiffening and shaping the fabric into flexible, bespoke panels.

The project proposes a construction paradigm rooted in distributed prefabrication. Complexity is intentionally embedded in small, easy-to-ship 3D-printed parts, allowing them to be fabricated anywhere in the world and combined with locally sourced bamboo. This approach reduces logistical effort, embodies a sustainable material ethic, and enables rapid on-site assembly. Thanks to its modular system, the pavilion was erected in just 48 hours.

Digital Bamboo illustrates how the convergence of computational tools, additive manufacturing, and natural materials can foster a more sustainable and imaginative architectural culture.

-

Dimensions: 9 x 9 m (footprint) x 5m height

Total area: 40 sqm

Total weight: 200kg

On-site assembly time: 48h

930 bamboo poles with 20mm diameter

380 connections in PA12, 1 joint in 316L Stainless Steel

35 sqm of shading panels

-

-

-

Marirena Kladeftira (Project lead), Matthias Leschok, Eleni Skevaki (Chair of Digital Building Technologies, ETH Zurich),

Davide Tanadini (Chair of Structural Design, ETH Zurich),

Yael Ifrah (MAS ETH DFAB coordination, Chair of Digital Building Technologies)

-

Maria Pia Assaf, Jomana Baddad, Frederic Brisson, Yu-Hung Chiu, Rémy Clemente, Ioulios Georgiou, Mahiro Goto, Anton Johansson, Laszlo Mangliar, Dinorah Martinez Schulte, Edurne Morales Zuniga, Fatemeh Salehi Amiri, Emmanuelle Sallin, Indra Santosa, Eliott Sounigo, Chanon Techathuvanun, Ping-Hsun Tsai

-

HS HI-TECH, Seoul, South Korea

Dr. Seungkyu Yoo (CTO), Yena Jung (Project lead), Hyunsoo Park, Sangjae Park, Seunghyun Baek, Heesang Jeong, Hoyeon Lee, Eungseo Kim, Yonghee Jeong, Jonghak Park, Hyowon Jung, Youngmin Joo, Younhyun Kim (Vice President), Ino Lee (Chief Executive Officer)

The development of the hybrid joints project in collaboration with HS HI-TECH is supported by the Bilateral Science and Technology Cooperation Program of ETH Zurich with an Innovation Partnership Grant (Project #IPG 02-112019 “AM for bespoke temporary structures.”)

-

Christian Egli, Tobias Hartmann, Michael Lyrenmann, Thomas Posur, Andrea Perissinotto, Andreas Reusser

-

May 2, 2021 – November 21, 2021

Biennale Architettura 2021, Venice, Italy, Giardini della Marinaressa

ECC ItalySeptember 29, 2020 – November 30, 2020, Zentrum Architektur Zürich, ZAZ Bellerive

Prof. Christian Schmid, Evelyn Steiner (Curator), Corina Hösli (Event coordination)