The Living Column

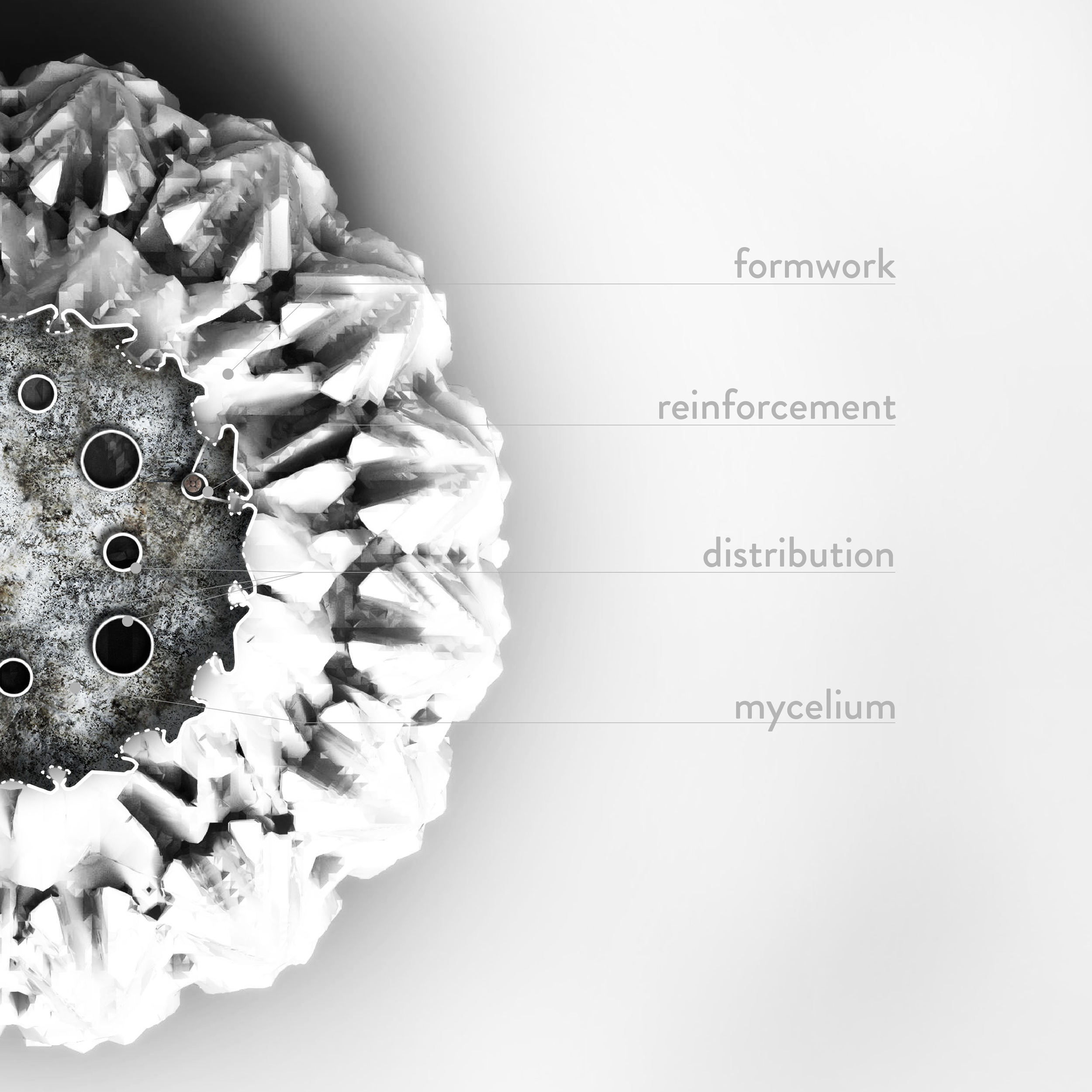

Mycelium-bound composites (MBCs) represent a rapidly emerging class of bio-based materials in architecture. Formed through the growth of fungal mycelium within an organic substrate, MBCs consolidate into lightweight, biodegradable and fire-resistant structural composites. Their fabrication relies on biological self-organization rather than energy-intensive industrial processes, offering a paradigm shift toward regenerative building materials. This research explores how architectural form, growth conditions and fabrication logics can be intentionally co-designed to enable new applications for MBCs.

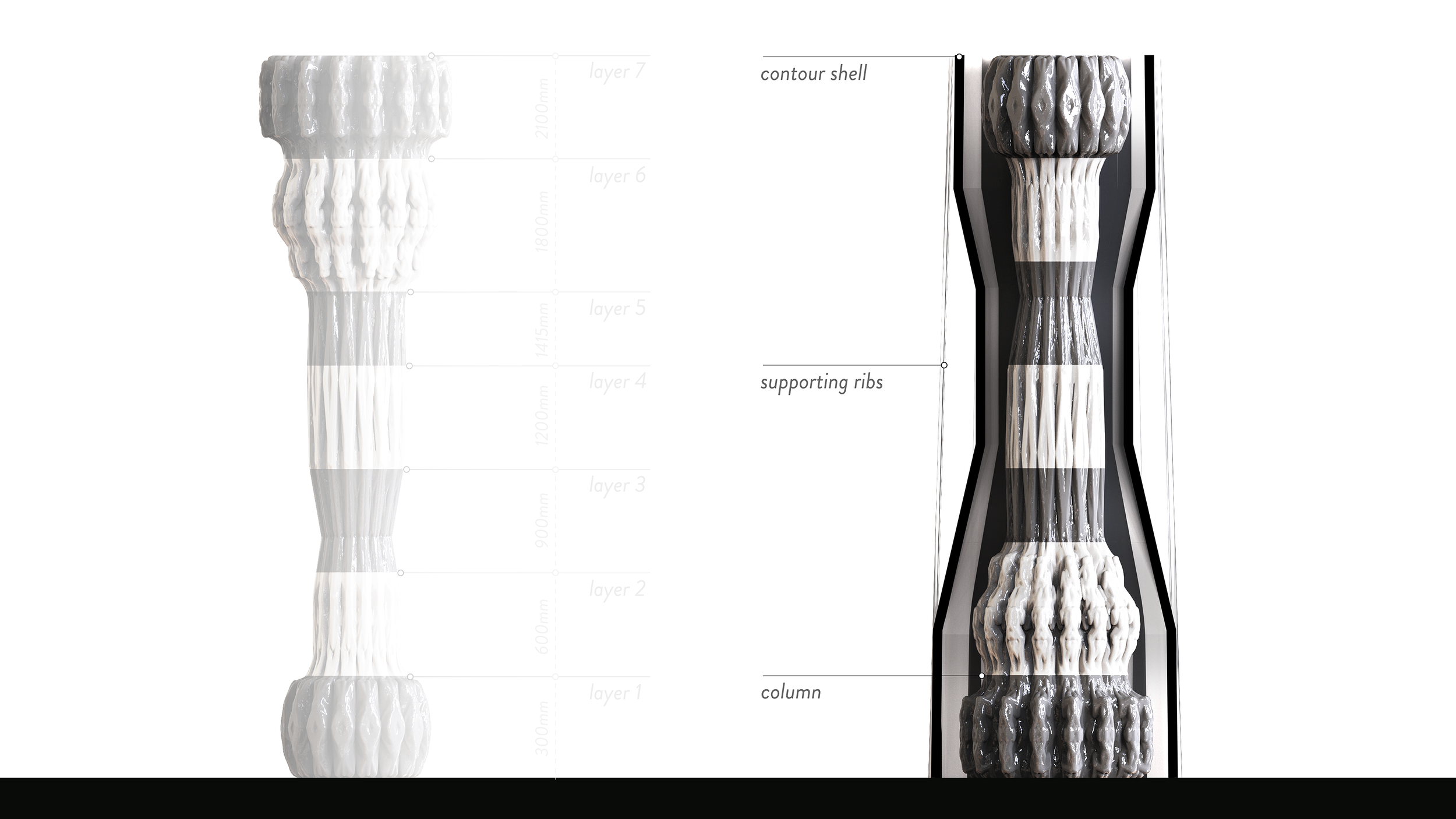

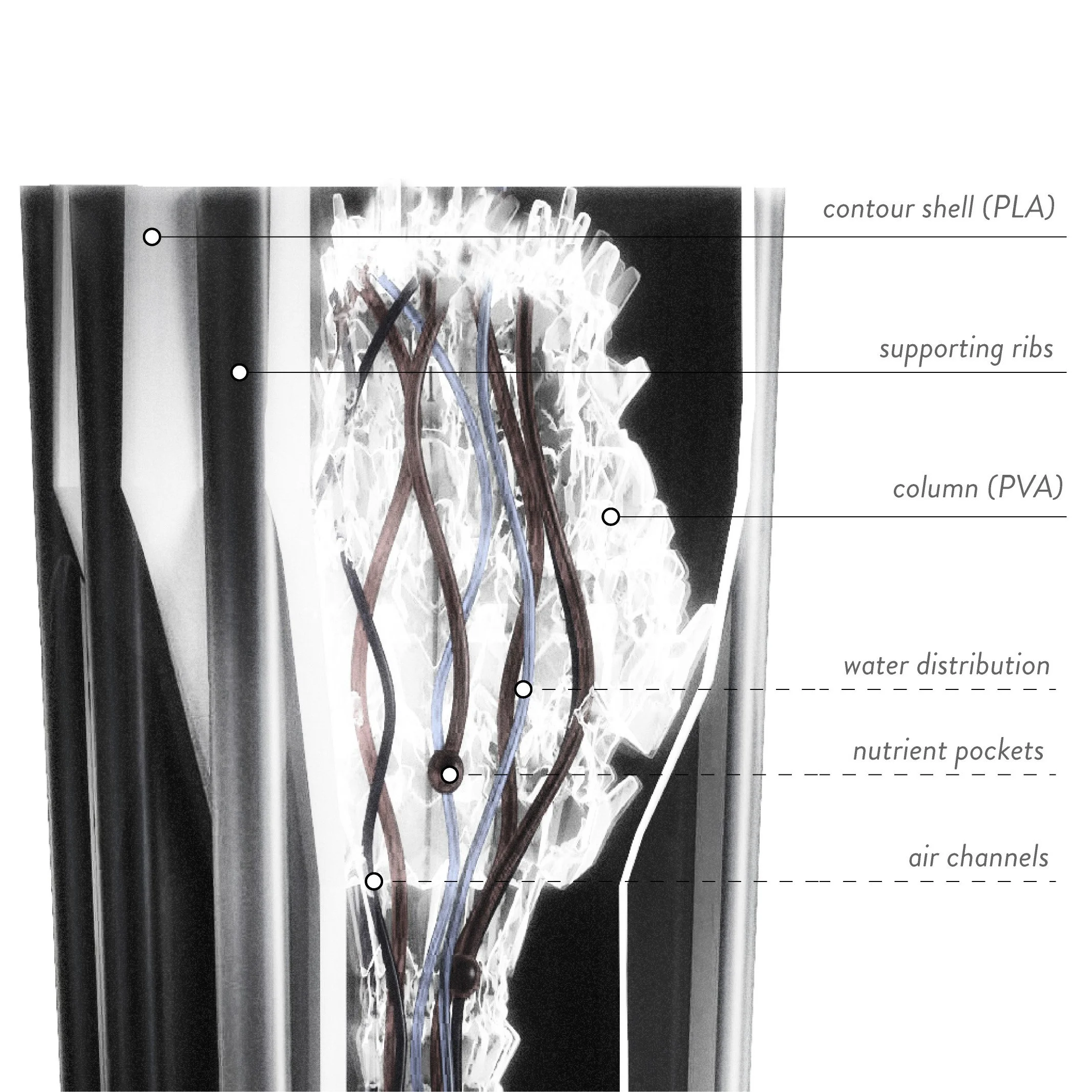

The Living Column is a full-scale architectural artifact grown from living biological material. Its geometry is defined by a highly engineered 3D printed formwork designed specifically to host, guide and support biological growth. The formwork, produced from a water-soluble polymer, acts as both a spatial mold and a micro-environment that facilitates the formation of a mycelium-bound biopolymer.

This project builds on earlier work from 2015, when a 3D printed chair was fabricated using a living mycelium substrate that consolidated into a dense biopolymer matrix during growth. Extending this line of inquiry, the Living Column investigates how more specialized and biologically compatible 3D printed formwork can enable larger-scale architectural applications.

The formwork integrates features that optimize environmental conditions for mycelium cultivation. It provides shelter, nutrients and humidity, while simultaneously defining the structural geometry of the column. Once growth is complete, the formwork is dissolved in water and recycled, leaving behind a consolidated, load-bearing biopolymer.