Add-on 3DP for Bespoke Textiles

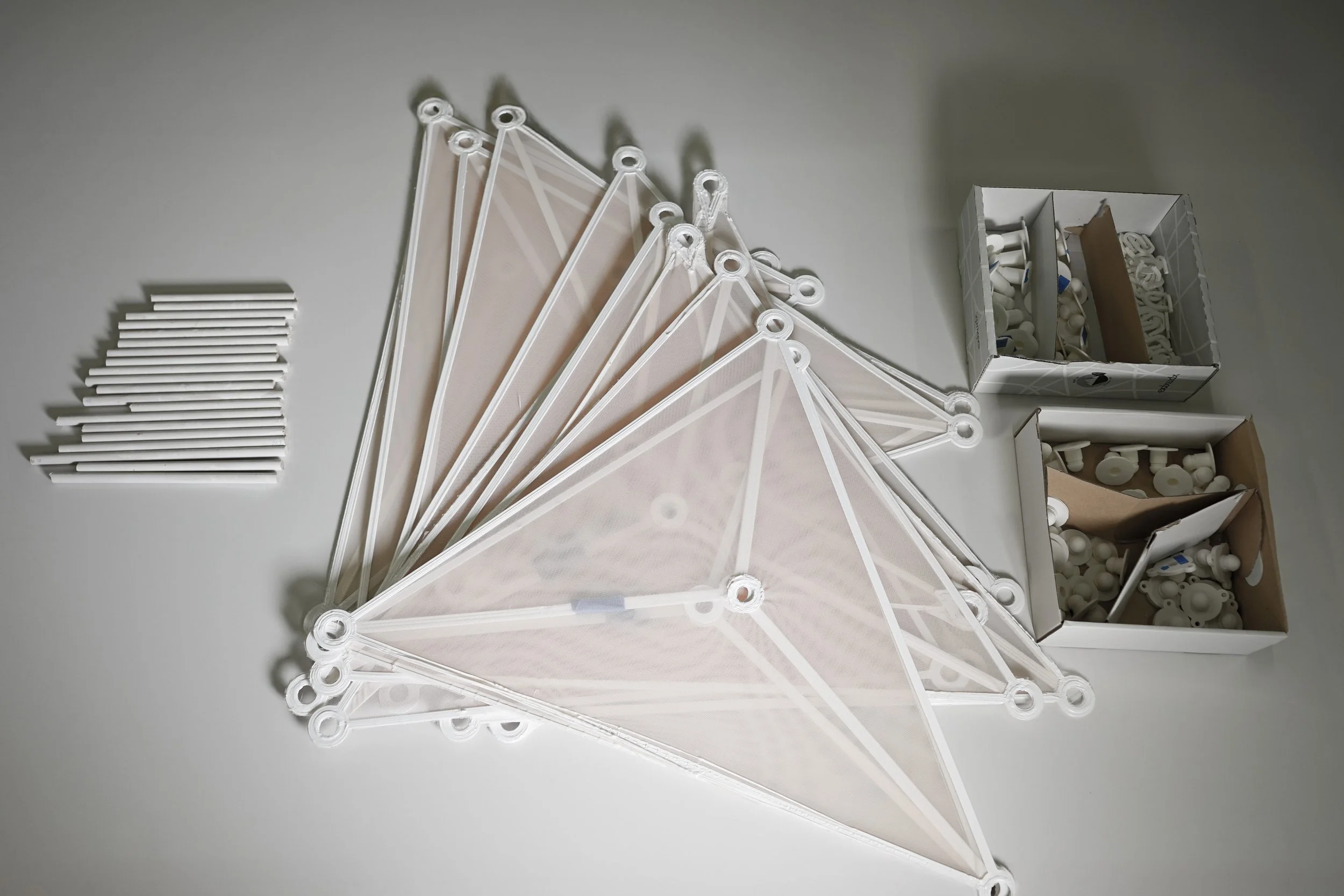

This research investigates how fused filament fabrication can be deposited directly onto textile substrates to create ultra-lightweight, spatial skin elements at architectural scale. By combining a soft, stretchable fabric with rigid 3D-printed material, the work develops a new composite system that can be rapidly fabricated, shaped, and assembled into bespoke shading or façade components.

A series of material tests established the behavior of this hybrid composite. Nylon and Spandex fabrics were paired with PLA, TPU, and PETG to study adhesion, stiffness, and failure modes. Elongation tests showed that add-on 3D printing increases in-plane stiffness by 15 to 20 percent, while simple structural bracing experiments demonstrated significantly improved stability compared to pure fabric. The research also identified conditions such as excessive tension that lead to controlled delamination, a phenomenon later used intentionally to shape the textile into three-dimensional forms.

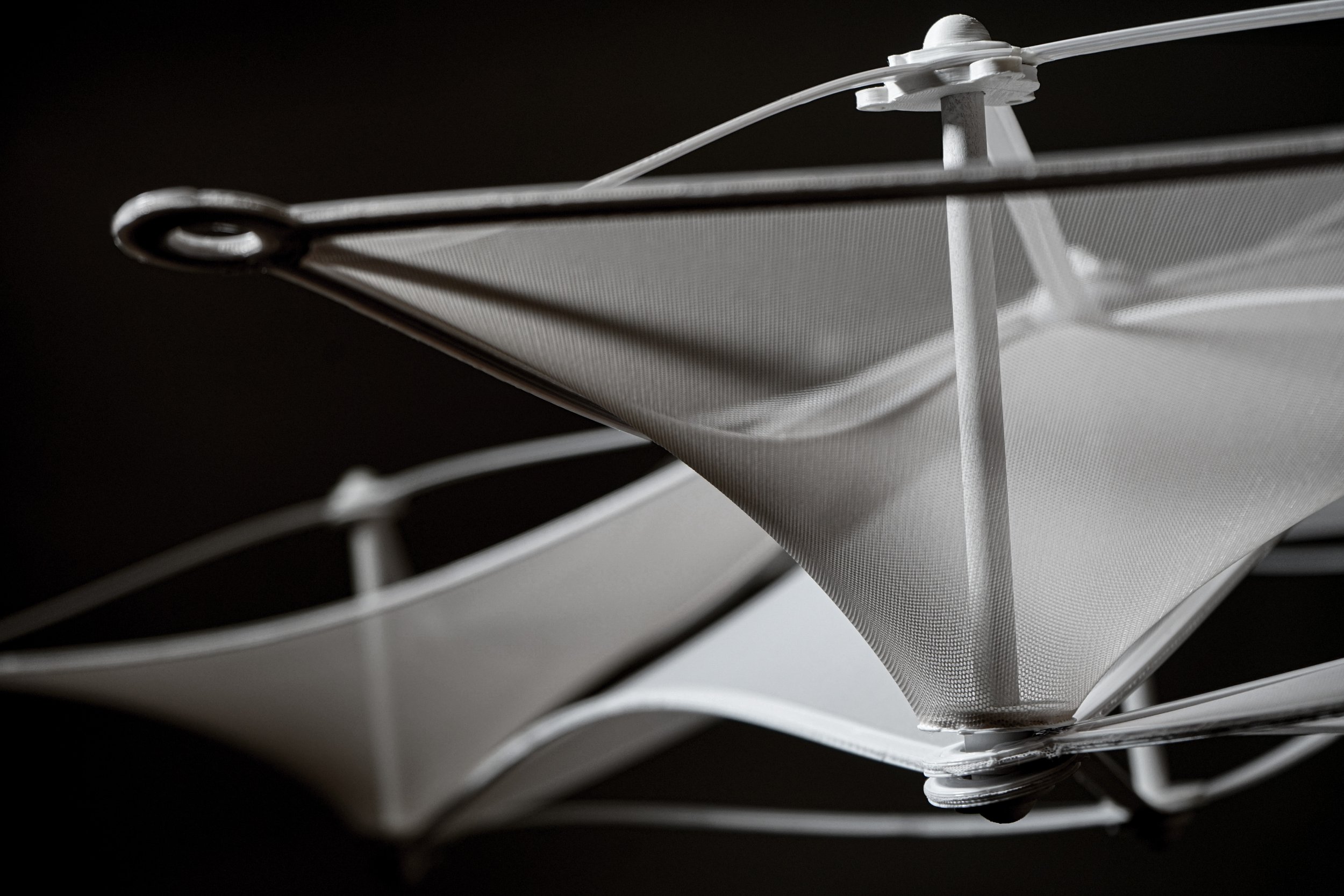

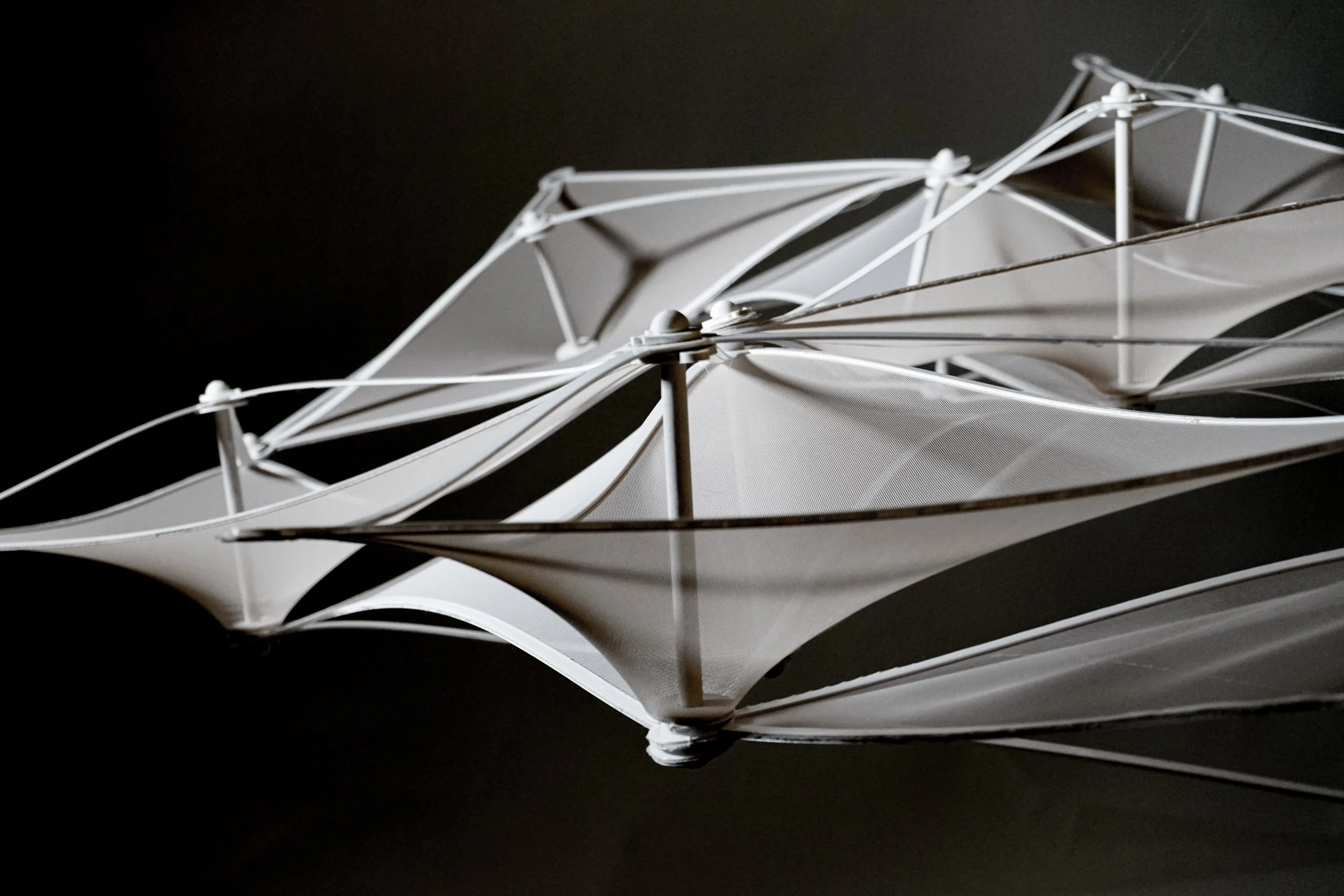

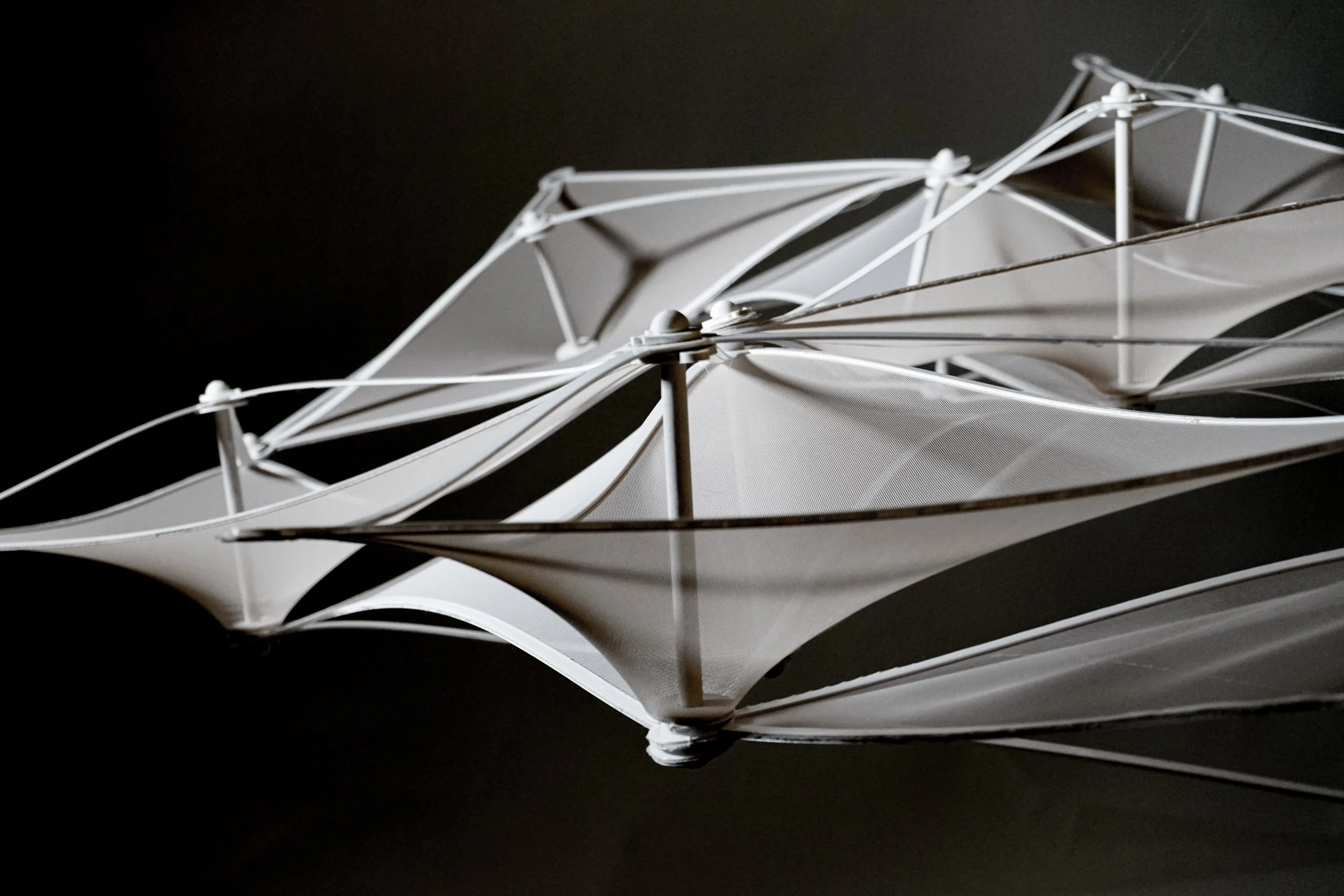

Building on these findings, three transformation strategies were developed: active textiles that self-fold through discontinuous printing on stretched fabric, folding elements based on printable deployable geometries, and tensegrity-like elements that use programmed delamination combined with compression rods to generate spatial depth. The tensegrity approach, which activates the fabric in tension and the printed material in bending, proved most suitable for architectural scaling.

These methods were validated through multiple large-scale prototypes and a final demonstrator, a 21 panel shading canopy measuring about 2.5 by 2.4 meters. The system is extremely lightweight, flat-packable, and rapidly assembled through an integrated clipping connection logic.

The research shows how add-on 3D printing on fabric enables new architectural applications, from temporary urban canopies to retrofitted façade shading, while minimizing material use, enabling customization, and expanding the design space beyond conventional polymer extrusion. Further research could focus on industrial production, embedded actuation or lighting, and new functional morphologies for adaptive building skins.

-

Emanuelle Sallin

-

Matthias Leschok

-

-