Mini-HC3DP

Mini-HC3DP is a hands-on teaching module within the MAS DFAB program that introduces students to Hollow-Core 3D Printing using robotic fabrication systems. The course familiarizes students with the principles of HC3DP and situates the method within a broader discussion of material efficiency, structural performance, and geometric control in additive manufacturing.

Filament-based HC3DP setups were prepared in advance to allow each student group direct access to the fabrication process. Participants learned the complete workflow, from toolpath planning and robotic control to the calibration of HC3DP specific parameters. Emphasis was placed on understanding how machine behavior, extrusion dynamics, and motion strategies directly influence material performance and spatial articulation.

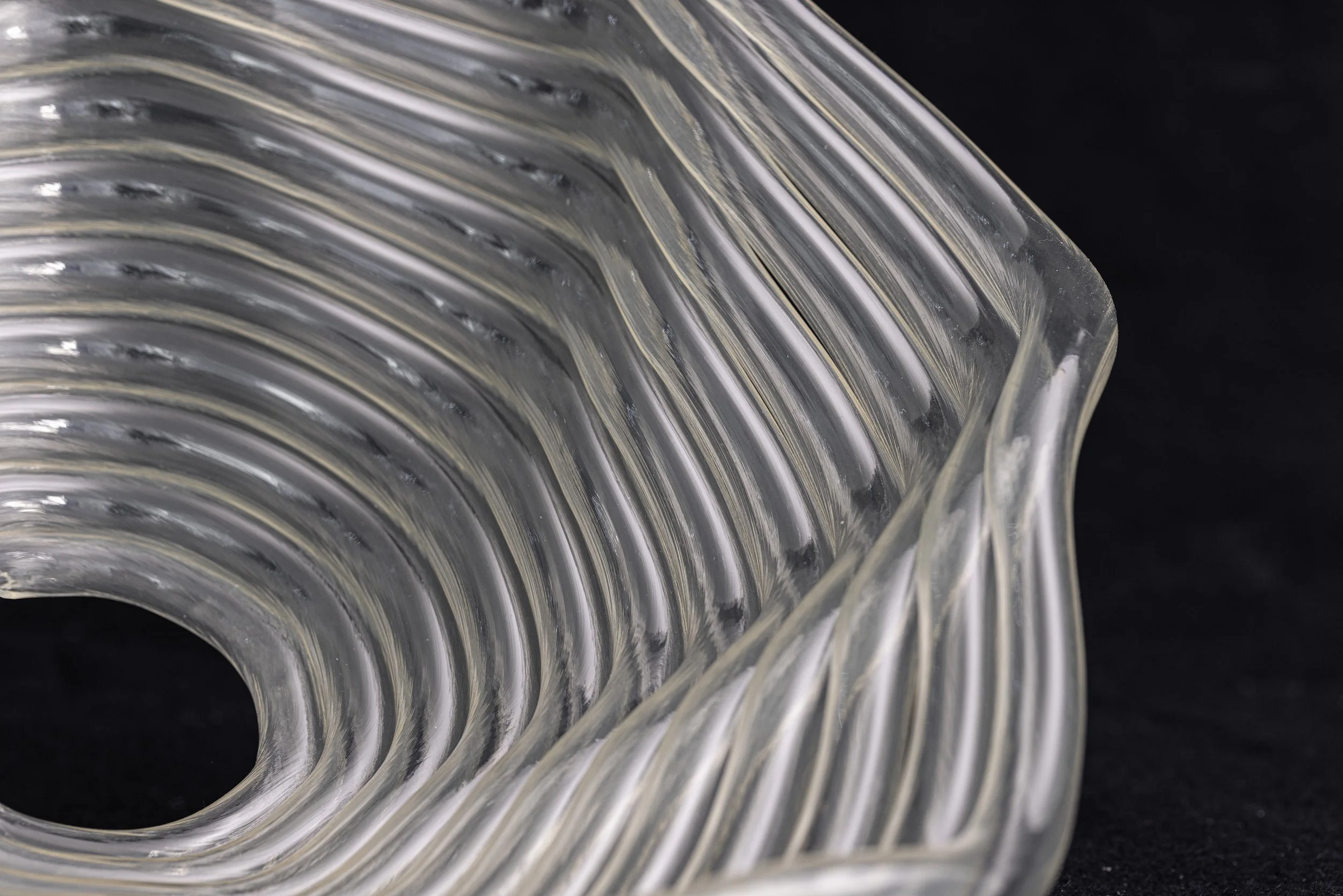

Through a series of experimental prints, students produced a range of artifacts and architectural design elements that explored the unique characteristics of HC3DP. Investigations included advanced toolpath manipulation, variable cross sections, and controlled beard detachments, encouraging students to move beyond representational printing toward open-ended experimentation.

The course served as a preparatory platform for the Protoplasto exhibition, enabling students to translate technical understanding into spatial and material propositions at an early stage. By combining robotic fabrication undertaking with hands-on experimentation, Mini-HC3DP bridges technical training and exhibition-scale design exploration within the MAS DFAB program.

-

Eleni Alexi, Adam Anouar, Ana Ascic, Keng Chia Chang, Xue Chen, Po Yen Chen, Ahmed Elmeraghy, Caitlin Emily Gallagher, Yixiao Huang, Yi Hsiu Hung, Chenming Jiang, Lihin Karunadhipathi, Joseph Kenny, Man Ki Ian Law, Pedro Lopez Moldano, Nijat Mahamaliyev, Abhipsa Pal, Carl Pantos Conquilla, Etienne Pavoncello, Huang Su, Lee Yo Cheng, Zhuo Zhang

-

-